You might remember some of the articles that I posted from Portland in the last few months, such as the one on SCCA race cars and a behind the scenes on RaceEnergy Honda team. This is the last post in that vein for now, and I saved the best for last, at least for the car geeks like me. An in-depth look into a professionally build SCCA GT3 car based around a 2006+ FG2 Honda Civic Si coupe.

Construction of this car began almost by accident, when Jim Hargrove, who was campaining his ’76 Civic GT Lights car in SCCA at the time, visited Ontario and saw the molds being taken off for an IMSA style Civic race car. He immediately liked the shape, and having raced his ’76 Civic, I’m sure brand loyalty had a part to play in the heavy interest as well.

Originally thinking of replacing the GTL Civic with this new one, Jim had the initial Civic body made and sent over to Robinson Race Engineering in Cumming, Georgia. They soon found the body was too big for the GTL rule set and the car would need to be built for the faster, larger, GT3 class.

Once they decided to build the tube frame car for GT3, a couple of engineers from Honda’s Dayton, Ohio R&D facility showed some interest in helping the motor development of the car unofficially, in their free time. They made the choice to use the largest of the K series engines, the K24, and would build it for a torque based power band rather than an all-out horsepower dyno queen.

The problem with using the large K24, the car must run a 31mm restrictor mandated by the SCCA. With the combination of the engine, sequential transmission, and solid axle rear end, the car had to meet a minimum weight of 2,222lbs, which would make it the heaviest in its class. With extra vehicle weight, comes larger fuel consumption, as well as tire degradation being a bigger issue than the lighter cars over long races.

The entire Honda K24 was gone over before going into this car, a very extensive build. It retains the stock crankshaft, but the counterweights are lightened, knife edged, and Teflon coated. Con-rods are courtesy of Crower, and some custom pistons that produce a heady 14:1 compression ratio.

The valves, locks, and springs were custom made by Motorsport Engineering, as well as the custom ground camshaft. VTEC has been disabled on this car since it will generally live in one RPM range and the benefit of VTEC would be seldom if ever seen out on the track.

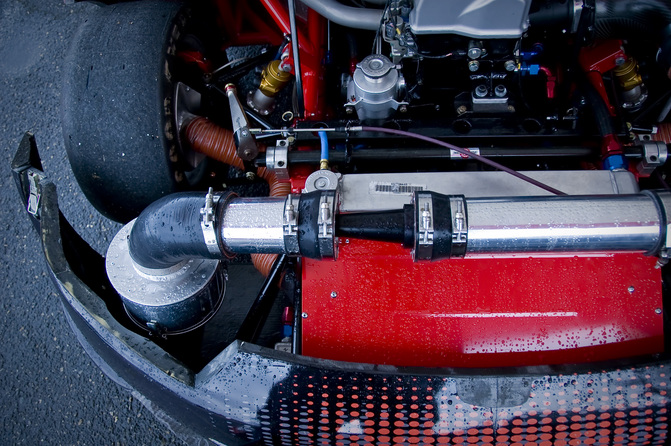

Kinsler 50mm individual throttle bodies are mated to a custom dry carbon Motorsport Engineering intake plenum. This unit is specifically designed to pass SCCA’s mandatory stall test, and looks freakin’ awesome to boot.

The header was custom made for this car by Motorsport Engineering as well; it’s a triple-Y setup, mated to a custom exhaust with a Burns Stainless race muffler.

You can also see the air jack system nestled behind the front wheel in this shot, all plumbed to a central attachment location for when the car comes hot into the pits.

All of the engineering that went into the engine results in an output of nearly 200lb/ft of torque and 270hp at 7500 rpm breathing through the 31mm hole of the restrictor. Un-restricted, this car would make closer to 350hp!

Jim and the other guys designing this car figured this car would make a good endurance car so a few alterations were made to it to prepare for the time they decide to race the 25 hours of Thunderhill or a similar event. A Cool Shirt system was added, which is an added bonus in those hot days at the track even in short stints, as well as wiring for the headlights.

The car typically runs a 10 gallon sprint sized fuel cell, but has the option for swapping in a 25 gallon Fuel Safe cell for the endurance races.

Some hand grooved intermediate wet tires, and full wets sitting on the shelf waiting for a rainy day.

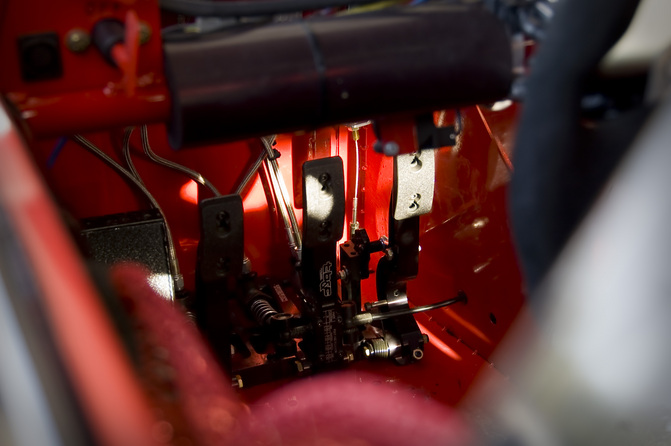

Fuel and oil pressure gauges are kept in plain sight, far ahead of the steering wheel and digital dashboard. You can also see the top of the triple Tilton master cylinder reservoirs for the brakes and clutch.

A very driver centric interior is a result of a custom made race car, compared to uni-body production based vehicles converted to race cars.

The car is run by a combination of Motec and Race Energy electronics. A Motec M800 is the central brain and utilizes a Motec PDM15 Power Distribution Module, to switch power to the starter, coils, injectors, lights, wipers, fuel pumps, differential, and transmission cooler pumps. The Motec system operates in a closed loop with a lab grade lambda sensor.

All information other than mechanical oil pressure and fuel level, is sent to the AIM MXL Pro dash. The digital dash also records wheel speeds for all 4 wheels, ride height and shock positions on all corners, steering wheel position, brake pressure front and rear, lambda, actual battery voltage and current, and 13 other params from the M800 ECU via Canbus connection.

The Tilton fully (and I mean fully) adjustable pedal set is such a nice piece of kit. Making adjustments is a breeze, and is fully configurable to suit the driver. Dual master cylinders obviously help split the braking duties to both ends of the vehicle, allowing adjustable bias on the fly.

The chassis is engineered and build by Robinson themselves, uses double A-arm suspension up front and solid axle in the rear. Performance Friction brakes are more than up to the task of endurance racing, and simply overkill for most sprint races.

You’ll notice 4 lug hubs, not sure if these are mandatory, or just to save weight, but does produce a simpler set up in the front.

You can see the custom Winters Mini V8 quick change rear axle. Installed is a set of 3.78 gears, provided by B&J engineering, and can be swapped with 4 other rear ratios to suit the tracks.

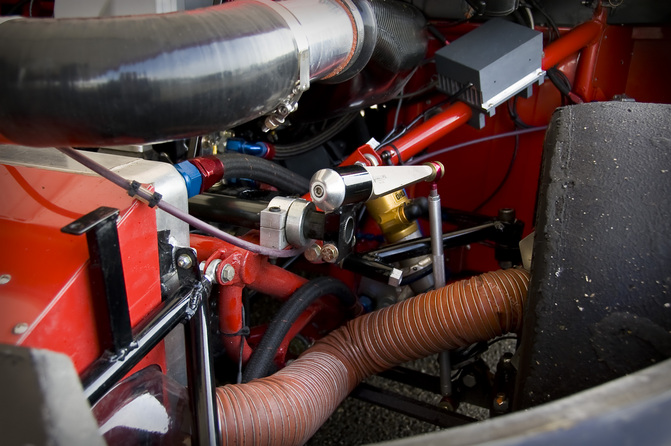

The axle is connected to a 5 speed sequential transmission made by Tractive in Sweden. The ratios were picked specifically to mate with the power band of the built K24. A Tilton Silver Crown bellhousing, Tilton Super Starter, and Tilton triple plate 5.5″ metallic clutch transmit the power from the engine to the driveline. This transmission and clutch combo can take the beating of more than 450hp so easily tackles what this Civic can dish out and should be very reliable.

Wheels are 15×7 Bogart Racing Wheels, the size being mandated by SCCA in this class, running bias-ply slicks to get maximum rubber on the track.

The entire body of this car is made from carbonfibre with Dzus fasteners holding all of the panels on. Each panel only weights a few pounds, with the whole body weighing in less than 100lbs.

The car also runs a dry sump system which helps getting the engine as low as possible down in the chassis. Dailey Engineering provided the pump as well as the pain. The large dry sump tank is situated on the passenger side of the interior, separated by a firewall. The placement helps the weight balance of the car.

Both front and rear feature Speedway Engineering anti-roll bars, with adjustable blades, one being adjustable internally, and one externally. This way Jim could adjust the sway bars in an enduro race to compensate for the weight loss because of fuel being burnt off during long stints.

The car stays in touch not with AT&T, but with Ohlins TTX MkII 4-way adjustable shocks and Hypercoil springs, definitely some high end dampening, not even sure where to start with 4 way adjustable dampers! Also check out the removable front sub-frame, in case of an accident, the entire front assembly of radiator, shroud, and brake ducts can be removed quickly for repairs.

Had to post another shot of the pretty carbonfibre work and black powder coated Kinsler ITB’s.

This car made its race debut last year at the SCCA Runoffs at Road America, starting in last place because of some technical teething issues, but ended up placing 9th overall and winning the Sunoco Hard Charger award. Keep your eye out for this car at this year’s Runoffs!

I think Jim has one of the most badass Civic race cars in North America, maybe the world? What do you guys think?

Also, if you want to see this car and a lot more really wicked race cars out on track soon, come out to Portland International Raceway for the upcoming Double National weekend on July 1st, 2nd, and 3rd! I’ll be there with the Race Energy crew taking more pictures and trying to lend a hand, getting Jim and this car onto the top step of the podium!

EDIT:

Here are a few comments from Jim regarding some of your questions and comments below.

– The solid rear axle is not completely mandated by the SCCA,

but the penalty for IRS is too severe. The base car weight is 2195 lbs. Add a

1.25% weight penalty for the sequential transmission brings the weight to 2222

lbs. IRS would add another 5% to the base weight, or 110 lbs which would render

the car completely uncompetitive.

– We also hated the super long piping from the air inlet to

the plenum. This has been addressed and a new system was in the car for

Portland. (Carl, you probably have shots of it).

– I don’t think the rod ends in the A-arms are in any kind of

shear or bending. The arm pivots about the center of the rod end and the shocks

are separately linked to the chassis.

– Jim Dentici is a very good friend of mine. The only

difference between this car and his is that his is front wheel drive and ours

is rear wheel drive. The are both tube frame race cars with replica bodies.

– Our GTL 1976 Civic is a unibody or tub car. To make it stiff

enough for racing (try 1000 lbs per inch springs), we basically built a full

tube frame into the unibody. All tub cars are now built this way – the tub is

not actually doing any work other than providing shape to the car.

– The other problem with a tub car is crash damage. A full

tube frame car is very easy to repair after an incident. Simply cut off the

damaged parts, weld on new tubes, repair or replace the body panels and you are

back in business virtually overnight. A tub car requires much more tlc to make

right, and is far easier to write off, so a tube frame car is a much better

investment. Many tube frame cars have life spans of 20 years or more, and can

be rebodied from time to time to keep them current.

– Keep in mind that the GT Division is basically for tube

frame replica cars built to the highest level of performance. Moving down one

level to Production puts you where all the cars are unibody. All the pieces on

a Production car had to have been used on that model, although engine

preparation is pretty open. We typically find that the brakes on a Prod car

start to give up later in a race, so even if the car was more powerful and

faster in a straight line, they start to come back to a GT car towards the end

of any race. Better suspension geometry usually keeps the tires under a

GT car longer than a Prod car as well.

– Carl Jarrett

cool for the engineering aspects... but calling this a civic is a complete joke. no k24 ever came in a civic, no civic was ever RWD, not a bit of this chassis has a resemblance to a civic... complete custom tube-frame race car that happens to have a civic shell. and a custom-molded widebody carbon civic shell at that.

Simply

Amazing

Speechless...

Sick !

@jay dub the new Civic SI's have a K24.

I Jizzed

@jay dub Well, atleast it still has Civic headlights, grille, and taillights lol. :]

2011 Civic SIs indeed came with K24s as will the future models. Check your facts before you spout off like that. On the other hand I happen to agree with most of what you said. Civic-bodied race car is more appropriate. All I can keep thinking is why for the love of God would such a "modern" race car run a solid rear axle. They obviously had the money and the skills to build a custom independent setup.

i agree with jay dub in that this is hardly a civic (just like most Formula D cars are hardly what they pretend to be) but this is still some pretty ill shit

If we are getting technical, the new Civic comes with a K24. But really who cares, what else would you call it? Its skinned like a Civic, has a Honda powerplant, that to me is enough for it to be deemed Civic worthy.

Agree with Jay. Not a Civic, and there might be a massive engineering effort gone into this. But it doesn't impress me that much, I'd much rather see a real Civic converted to race car.

Who cares if they call it a civic or not. Great feature, great engineering, thanks for publishing this!

Great engineering here which gives us a lot of insight into race car building but I'll agree with Dennis that it'll be way cooler to actually convert a monocoque-ed Civic into a race car.

That'll be fun.

Interesting... Really digging the engeneering. Solid rear-axle? Why?

Awesome fitment

oh man i thought this was a drag car when i first saw it :s!

Reading through the whole feature has left me speechless. The amount of work undergone on the car is simply amazing, so is the choice of parts, let it be suspension, engine, body fabrication. Personally, I believe that this guy owns one of the best Civics around

a massively tachnical feat of engineering, 'jay dub' is the man of the post. so i think the post title could've read "Civic-shaped GT-3 Carbon Bodied" racer..

Great coverage of a seriously amazing GT3 build. Thanks for including some technical insight too -- would love more of that here.

That's a beautifully built GT car. Brings back memories of when I was flagging for SCCA in the New England Region at Lime Rock Park. Also takes me back to the heyday of IMSA in the 80s and going to see the GTP/GTO/GTU races at Watkins Glen.

To those who say this isn't a Civic, I do understand your point of view. Purpose built silhouette cars are not exclusive to the USA, but it is a cultural phenomenon of this country to build tube frames instead of basing off the uni-body. Keep in mind most properly built race cars, even if based on the uni-body, have very little in common with their street-born brethren.

Great write-up, looking forward to more after the double national!

A-meh-zing

I agree with the masses. Awesome engineering.... but that's as much as civic as a RC car with a civic shell is.

IMO the BTCC civics are the best racing civics close to the originals but clearly built for the track

@Brandon...these races are generally done on smooth pavement (as far as i know, and on smooth pavement an IRS is really not any better than a LRA.......its the bumps that kill ya!

That is very american way of building a race car.

2010 Runoffs: GT3 Race

http://www.speedcasttv.com/scca/#/races/226

That is very american way of building a race car.

@jay dub

In NASCAR, the Chevrolet Impalas, Ford Fusions, Toyota Camrys, and Dodge Chargers aren't even close to the real street cars, but they're still called Chevrolet Impalas, Ford Fusions, Toyota Camrys, and Dodge chargers. Explain that.

Wow, most of you would have hated the '80s and '90s and probably can't stand IMSA and Grand Am. A race car then, as it is now, a tube-frame car, especially in the top ranks of racing. I just don't understand the hate on the tube-frame race car. It is the most amazing, technological piece of engineering this side of a modern building. I mean, look at cars from the DTM right now, they are not cars built into race cars, they are bred and built race cars just like this GT3 Civic. Gran Turismo, while helpful to bring road racing to a younger generation of Americans, has really ruined the imaginations and expectations of those same kids.

@Jay Dub the newest gen civic has a K24. Stop being so angry its a race car based on a civic chill and enjoy.

the chassis and suspension were done to SCCA's ruleset. And for tinker toy GT cars, they mandate solid axel rear ends...its a hold over from the 60 and 70s. now if more Americans with a world view on racing would get into SCCA maybe the rules would change for the better.

Oh you can find the SCCA rules here http://www.scca.org/contentpage.aspx?content=44

BTW that is one bad ass GT3 car! Hopefully it will be at the runoffs in a year or so.

Very cool to see a spotlight on a true SCCA club car... granted, this car cost more in parts/labor and development time than MOST club racers would ever spend. But nevertheless, very cool to see this on speedhunters. Id love to see more coverage of GT and Prod cars. Maybe a feature on one of the Dentici/old King Motorsports GTL CRXs... or one of the Prather built F/E Prod Miatas, etc...

Looks nothing like a civic but it is pretty damn awesome! First civic I've ever said that about.

I hope the solid rear axle was mandated by the rules!

Also the super long piping between the restrictor and plenum is weird (why not move the filter to the other side?), and the upper a-arms have rod ends in bending.

I call it a a master piece