We often forget that one, if not the most important, aspects of motorsports is the development of new technologies. Pretty much every last bit of gadgetry, innovation and evolution that has been applied to your everyday road car has in some form or another trickled down from its original use in motorsports. From turbocharging and fuel injection (mechanical & electrical, indirect & direct) to automated gearboxes (single and double clutch) and everything in between has come to us thanks to the million of dollars of research and development and outright testing that manufacturers do along with their race teams. While further evolution may seem difficult considering how far the internal combustion engine and the motor car in general have come in the last 100+ years, there are still plenty of ideas worth exploring, especially seeing the pace at which hybrid and electric motor technology is advancing. And this is exactly why nerding out on some technical stuff now and again can really be exciting, especially when you can see the obvious links and potential that it can all have on future sports cars.

After seeing the awesome performance of the Audi R18 e-tron quattro at this year’s Le Mans I decided to read up on the car’s driveline and power train, just to see what on earth made it so blisteringly quick and outright untouchable. Needless to say I was impressed by what I discovered.

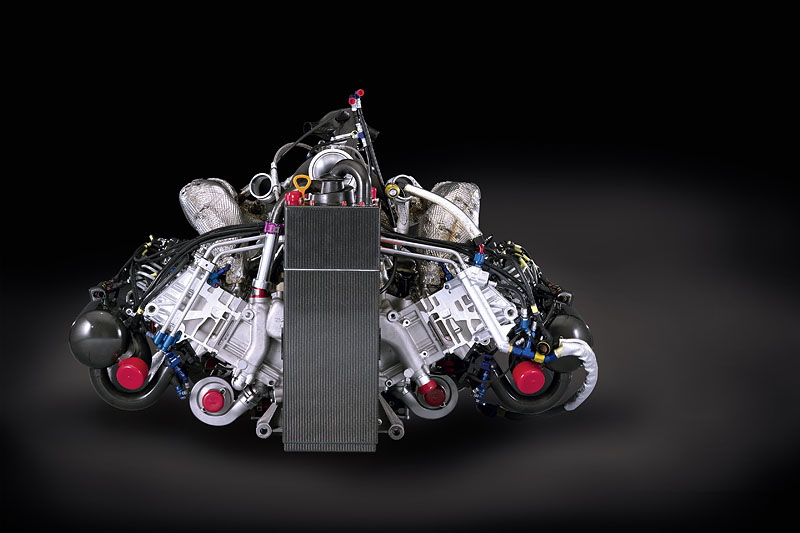

While it’s very interesting that Audi partnered up with Williams to develop their hybrid e-tron (AWD) drivetrain, which functioned rather differently to the Toyota TS030 KERS system (RWD), it’s the engine side of things that really grabbed my attention. Audi serves as the perfect example of how R&D can be applied to not only adapt to new racing regulations, but also push technology to extremes. Back in 2006 when they first won Le Mans with a diesel-powered car, the R10 TDI, they were running a twin-turbocharged 5.5L V12 monstrosity of an engine. This year’s R18 e-tron quattro managed the same feat with an engine running half the numbers of cylinders, 32% less capacity but able to power the car, along with the e-tron hybrid AWD system, to faster lap times. Amazing as that may be it’s the actual way in which they designed the 3.7L turbocharged V6 diesel engine that is most impressive…

…and notice I said turbocharged, not twin-turbocharged. That’s because Audi, along with its long- standing turbo partner Honeywell Garrett came up with the “monoturbo.” It’s a simple idea but one that has required a rethink of some key engine aspects, most obvious of all the angle between the two banks of three cylinders, set at 120 degrees, and the exhaust side of the heads which have to obviously be located towards the inside of the “V”(hot side inside if you will). This allows the two exhaust manifolds to connect up to the hot side of the turbocharger and flow exhaust gasses radially into it, spinning the turbine via its variable geometry vanes. Once they have done their job exhaust gasses are dumped through the axial outlet that you can see above, onto the exhaust itself.

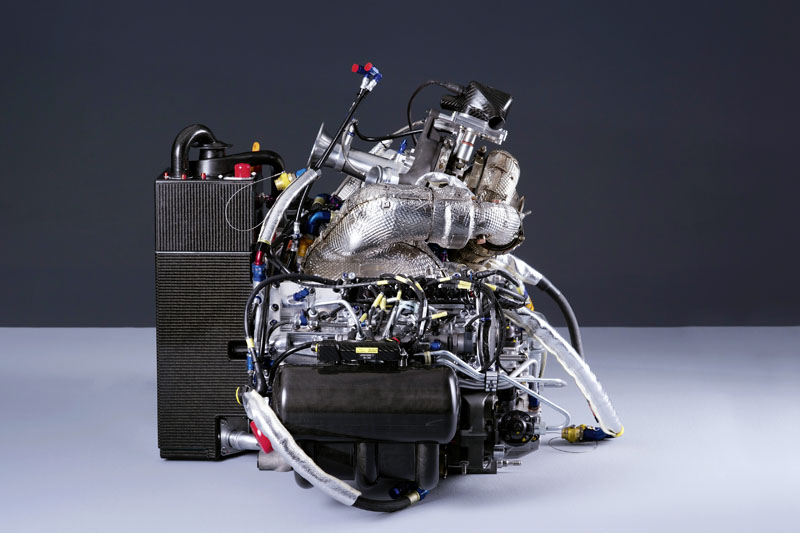

Here is a better view of the monoturbo, its hot side towards the bottom, wrapped in heat shielding and the compressor side, which seems to be coated in some kind of heat-resistant ceramic finish. Once aspirated through the intake restrictor the air gets compressed in the visibly small compressor (designed this way to allow the best possible response) and then sent to each bank of cylinders…

…via the two above outlets. The carbon fiber enclosed control unit on top of the turbocharger assembly controls the Variable Turbine Geometry (VTG) system, which continually adjusts the angles of the vanes on the turbine wheel to make sure there is no lag in throttle response and power. This is also guaranteed during gear shifts, thanks to clever use of electronics, something that apparently surprised even the ACO, the Le Mans organizer when the technical stewards were going through the engine data.

It’s all fascinating stuff and hopefully technology that will eventually trickle down onto road engines, and maybe also gasoline engines. BMW has already done something similar when it comes to turbocharger placement in their current generation of twin-turbo V8 gasoline engines that power the 5, 6, X5, X6 and 7 series (including the M5, M6, X5M and X6M). The V8’s “hot side,” like Audi’s TDI V6 monoturbo, has been located on the inside of the “V” and the two turbochargers positioned within it (literally on top of the engine). This, coupled with the cross-flow exhaust manifold which times offset pulses into the correct scrolls of the turbos, helps keep piping short and the adoption of charge coolers rather than intercoolers all make the engine as responsive as a naturally aspirated motor would be.

Here is a side view of the 3.7L TDI, where you can see the monoturbo placement and angle as well as interesting components like the carbon fiber intake manifolds and the carbon casing for the dry-sump’s oil tank in front of the motor. When looking at advanced race engines like this diesel V6 it’s hard not to wonder when we will be able to see powerplants like this make it onto production cars. I’d personally love to see a future RS model powered by something similar, gasoline of course! Maybe and RS version of the future R8? Audi failed a few years ago when they tried to twin-turbocharge the R8’s V10, with a pair of test cars catching fire on the Nordschleife. A centrally mounted monoturbo seems like the perfect solution, good for power, packaging and in the case of a mid-mounted engine, probably even cooling.

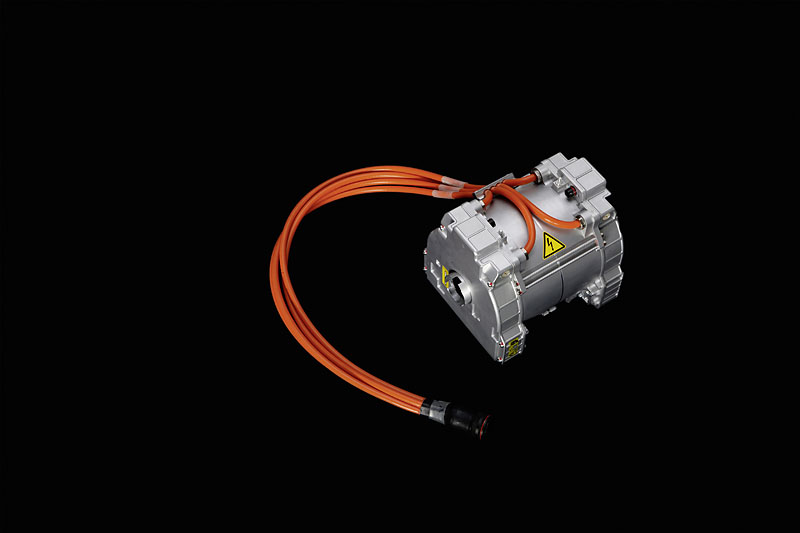

If that will ever happen it may well be joined by a similar hybrid system to the R18’s e-tron to power the front wheels. It’s all exciting stuff and as long as engineers continue to make these innovative engines feel as responsive and immediate as enthusiasts expect, then we have exciting times to look forward too.

The R18 also hides other interesting technology; of course composites make up the majority of any race car, and to save weight in critical areas Audi Sport even made the car’s gearbox casing out of carbon fiber. Pretty wild right?

Oh and let’s not forget the now-closed (new LMP regulations) tub part of the chassis, which seen here from this angle in its naked pre-paint state strangely looks like a closed cockpit F1 car!

What do you guys think, will the monoturbo developed in conjunction with Garrett Honeywell be something we can expect to see in the future on road cars? It makes sense in so many ways and is such a great example of the importance of motorsport.

Images courtesy of Audi Motorsport

-Dino Dalle Carbonare

That "hot inside" layout makes sense space wise. Why hasn't something like this been done long ago? Or were engines designed with turbos as an afterthought?

conventional materials and this think is gonna melt like a Candle.

Conventional materials and this thing is gonna melt like a candle.

actually you can credit the use of turbocharges on cars to the aviation industry, where they were first implemented.

What's the emphasis on gas?

The mono turbo has been around for perhaps 20 years now in diesel locomotives, the big breakthrough is making it smaller...

I want to see the intake manifold!! Nice desing

Whoa, that's full on. Love this kind of technical article. More please!

That's some crazy stuff right there. Keep the tech articles coming!

Nice article, congrats! Any wallpaper size pictures available?

@tanksnr: I think layout wise it was easier to place them by the sides to keep the engine compact in height. The center of gravity will be lower as well, especially considering that you won't find a lot of dry sump systems on normal road cars Another point is that it's a lot easier to have the exhaust coming from the bottom part of the engine towards the back then to get them from the topside, having to make some tricky bends between the engine and the firewall of the car...

In this car the placement of the engine in the car makes it easier to deal with that kind of problems...

Wow, incredible! Would love to see more stuff like this on Speedhunters.

Wallpaper would be great, especially that orgasmic monoturbo engine display. I can look at it for hours.

Great Read!! I would love to see this tech trickle into a street car, sooner rather than later. Would probably be the best selling hybrid on the market if it did.

awesome idea, loving the turbo design, don't know why it hasn't been done heaps before

Would love to see more of this kind of stuff.

hope to see this kinda tech into VR38DETT..

really great read, but why would you want gas instead of diesel? its better in every which way

Very interesting article.

Is Audi using the same VTG tech that is used on the 911 turbo?

It's funny how BMW got mentioned in the article when Audi themselves have already done the turbo placement in middle of the cylinder banks. The new 4.0 TFSI engine used in S6, S7 and S8 (with different internal modifications of course per model) uses turbocharger placement in middle of the cylinder banks and is even twin-turbo configuration. It's not a V6 but a V8 and it's nothing like the featured engine but it shows that the same technology is already getting implemented into the commercial sector. There is nothing fancy about the materials either; melting is not a problem when things are well-though and placed carefully.

Nice article, but a reverse-flow diesel engine with "monoturbo" VNT IS actually in production...right now...since 2010 actually: the Ford 6.7L PowerStroke. This engine also employs a Honeywell (Garrett) ball-bearing twin-inlet turbocharger, the DualBoost VNT, which has back to back twin compressors on a single shaft on top of everything the above turbo has.

@MarcAndreFontaine It looks like the two "pods" on each side are the plenums. Check out the length of the runners.

@El Duderino That engine needs more love, the technology in it really is amazing, especially for a heavy duty work truck.

@El Duderino That engine needs more love, the technology in it really is amazing, especially for a heavy duty work truck.

but the current v6 tdi has pretty much the same configuration. one turbo in the "v". it is placed sideways because the air filter is not located on the hood.

http://www.sport-cars.org/site_img/large/Audi-V6-3.0-TDI-Engine-2.jpg

better gas mileage? Less fill ups

@Tyler mielke Actually, diesel is much more economical.... you dont see pure gasoline cars routinely getting 40+mpg, or 6000lb pickup-trucks getting 20mpg's with gas..... thats the magic of diesel... oh, and you can make your own bio-diesel.

Many diesel/turbo-diesel vehicles routinely getting 600+ miles on one tank

The other benefit of diesel engines is the large amounts of torque they create, which is more important for daily drivers as the torque is available immediately and down-low in the rev range where engines normally operate. And the torque available, when driving on the highway is useful for passing.

The current setup is the traditional hot side outside, intake manifold and egr cooler is placed in the V with the turbo at the back hanging outside of the V. The new "hot side inside" configuration a completely different setup.

BAR F1 Team, begins developing carbon fiber caing (http://www.flickr.com/photos/scarbsf1/2229894079/in/set-72157603822715795/), Audi applies this knowledge on their cars. Very intereting article.

Very intereting article.

great photos and write up. that engine is probably one of the coolest looking i've seen.

@ClaytonPayton Next to the SR

Awesome article, and an awesome peice of engineering. Makes Mike Garret's features look like a joke.

aweosme stuff Dino!! thanks for sharing this...would love to see this engine in a road car....maybe next year at Gatebil with those crazy engine swaps!!!

That is pretty sweet!!! I would love to see that kind of engine design in a production car!!!!!!!!!

Nissan should make 2015 Nissan Stagea - 2.5litre Monoturbo engine with DCT gearbox. Oh and sell it in markets that like big wagons e.g. Australia, Japan and Europe.

With the large amount of M35 Stagea's I see in NZ and Australia you would think they were sold locally, but all of them are imports, so obviously the locals want a big Nissan Wagon with longitudinal 4WD/RWD.

@zipsandspacers Because I'd rather have a petrol/gasoline engine in my sports car, that's all. Not saying this tech couldn't be used on diesel street cars, they are obviously the obvious next step.

@ErwinCollazoNavarro @Tyler mielke I'd want gas if we were talking about a sports car. The monoturbo use on production diesel cars may be the obvious next step.

VTG has been used for some time on diesel engines. Porsche sort of adopted the tech for gasoline engines. The tricky part is the exhaust gas temperature on gasoline engines, meaning that a lot more time and development was needed to deal with this. That's why aside from the 997 Turbo not many others have taken this path...

They only reason I mentioned BMW is because, as far as I am aware of, have did it before Audi

@El Duderino I wasn't aware of that, great to see this application already in use in a truck like that

@Stilvia @ClaytonPayton LOL

@Nikhil_P Haha that would be awesome!

@AndrewThrift Nissan dropped the whole station wagon thing years back. They deemed a Stagea successor unprofitable and unneeded in today's markets...for them at least. I'm not even going to list how many awesome wagons are out there on sale right now...nor how cool wagons are!

@AndrewThrift Nissan dropped the whole station wagon thing years back. They deemed a Stagea successor unprofitable and unneeded in today's markets...for them at least. I'm not even going to list how many awesome wagons are out there on sale right now...nor how cool wagons are!

@speedhunters_dino @Stilvia what, can I not like the looks of an insanely complex and tech motor?

@speedhunters_dino @Stilvia what, can I not like the looks of an insanely complex and tech motor?

@ClaytonPayton @Stilvia Sure you can, good to see the SR being compared to motors like this

@ClaytonPayton @Stilvia Sure you can, good to see the SR being compared to motors like this

That engine is simply amazing. I cant imagine the response of spool time they are achieving. I sure with Toyota would get back into the FI world.

There is nothing new having the exhaust ports facing inside the V even with turbo(s) . Ferrari did a twin turbo F1 engine this way ages ago http://s1.aecdn.com/images/news/turbocharged-engines-in-formula-one-18108_5.jpgDoing it with a twin entry/exit single turbo is new.

The monoturbo idea could pretty easily be implemented into road cars. Seems like it would be a perfect fit for subaru engines. It will also be interesting to see what the tuners start doing when more VGV/VTG turbos start hitting popular cars. Besides full size trucks are there any vehicles out there using VGV/VTG tech right now?

@Jonas_dc Ah ok yes. Thanks for that insight.

Fantastic post. Great insight. Please more like this.

che tecnologia!!! e pensare che sulle nostre strade circolano ancora auto coi freni a tamburo...si potrebbe fare di piu' anche per migliorare le vetture di tutti i giorni

Wow finally some good info on how racing is important to transportation development. I argue with co-workers about how racing has saved there lives or saved them money in some way. From seat belt tech to diesel tech.

@robzor The problem with the Subaru motor would be a complete redesign of not only the motor but also the bay it sits in. subaru motors sit almost dead center in the engine bay, and the trans/front diff right behind that. This would make running the single outlet above the motor very tricky. The Subaru heads are also placed in the traditional way with the exhaust ports on the bottom of the heads causing them to flip their heads and intern making a whole new head/intake design. However I would not mind seeing a company like Cosworth dabble with this new idea.

I thought it was Jonathan Moore writing this until i read the signature. Haha..

Y u no post wallpaper?! o___0 :'(

Y u no post wallpaper?! o___0 :'(

Y u no post wallpaper?! o___0 :'(

Y u no post wallpaper?! o___0 :'(

I only wish this one was street legal and had a proper gasoline engine!

Tech Sex!!....i may be an idiot but this is just my idea though...instead of all the tricky piping and stuff couldn't you just have the exhaust ports empty into the "Vee" have a quasi turbo/intake manifold set up....err i mean like basicly design the hot side to exhaust into the "vee" and run the cool air around the sides...if anyone understands let me know like i said im no engineer....

Great stuff Dino. Its like I am reading Race Car Engineering or something lol.

@zackspeed333 Thanks man! That looks like a good mag, what I get here in Japan is Motor Fan, but rather than reading it's more like attempting to decipher it LOL

http://motorfan-i.com

@LavarBowers Sorry not following...isn't that what has been done already?

Let's hope it gets there! Maybe Nissan should look into this for the new 2018 GT-R? Maybe it would not make the engine sound like a vacuum cleaner?

@yanes33537 Name is at the top too;)

@hanablemoore And many other things...

@GabrieleBertaggia Si certo ma in paesi come l'Italia dove ti rompono le palle perche' fai modifiche sulle auto che cosa vuoi fare!

Thank you and noted! I've got something else coming up soonish...;)

@Steve4747 @robzor Not sure if it would work as well with a boxer front engine layout like the Subarus. Seeing half of the gearbox is inside the engine bay they have no space to locate ancillaries anywhere but on top of the engine (that's why they look so horrible, that alternator positioning is really bad!) Add a turbo on top of all of that and it would become a right mess. I can really see this monoturbo application work well with high end, mid engine cars that always have cooling issues due to (twin) turbo placement.

@CSAlltrac No spool time...zero lag! Imagine that. The NA guys would have nothing to complain about any longer haha

@speedhunters_dino upon re-Read you are correct. Touche' Dino sir...Touche' Now please tell them to make that sweet sweet hoodie in Fatboy sizes please.....=)

I believe general electric and electromotive, it may only be ge, have had a similar design on their locomotive engines for decades. Pretty awesome to see on a road car though.

awesome article! really intersting stuff

@speedhunters_dino I know. But usually I ignored that part. Bad habit. Haha..

@speedhunters_dino @GabrieleBertaggia secondo me non è tanto un problema legato al tuning,ma è qualcosa legato anche alle case automobilistiche....

@speedhunters_dino parlo di tecnologia ,non di tuning...non puoi pretendere di fare tuning in un paese dove vedi auto tamarrate coi freni a tamburo,colori da vomito e motore 1100...li in jap c'è un altra cultura

It seems similar in concept to the single compressor, twin-impeller turbo setup used on the current Ford 6.7 Powerstroke. It has dual impeller wheels, each spun by one bank of the engine, that drives the larger compressor side. Clever stuff!

looks like someone beat me to this observation.

Gasoline is dead look into the futuristic diesel engines that are more powerful and more fuel efficient.

If you haven't heard of black smoke drifting look into it and he supports very old and cheap technology.

@speedhunters_dino @zackspeed333 Race Car Engineering is a fascinating publication! Great post Dino!

@speedhunters_dino @zackspeed333 Race Car Engineering is a fascinating publication! Great post Dino!

@speedhunters_dino @zackspeed333 Race Car Engineering is a fascinating publication! Great post Dino!

@speedhunters_dino @zackspeed333 Race Car Engineering is a fascinating publication! Great post Dino!

DieselNuT They are a joke. Their low-traction "racing" has zero relation to modern diesels.

JamesMackintosh Actually they are nothing alike.

itsbiddle El Duderino Light duty actually. It isn't used in any Heavy Duty applications.

Diesel cars are not becoming more common. Most of the new cars coming out are petrol due to the engine being able to run at lower rpm's and have better compression. Which increases mpg and is more steadily available.

I think you will see it in some road cars in the future but the cost has to come way down for it to be available in most.

Relectric is a national supplier of new and reconditioned used and obsolete circuit breakers, electrical distribution and control equipment. http://www.relectric.com

Has all ready trickled down into the new 3.0tfsi single turbo V6

This is really sweet. I'm sure we will see this type of engine in production cars in the future once they can get the cost down. I would hope to see these within the next 10 years. http://switchon.eaton.com

I want to touch that car with my wiener!