Now to continue the detailed build story of Titan Motorsports insane drag Supra. Take it away guys.

With the car’s fabrication complete, the next step is to coat the raw metal in order to prevent corrosion. We are fortunate to have a great powder coater less than a mile from the shop that we contracted to coat the chassis.

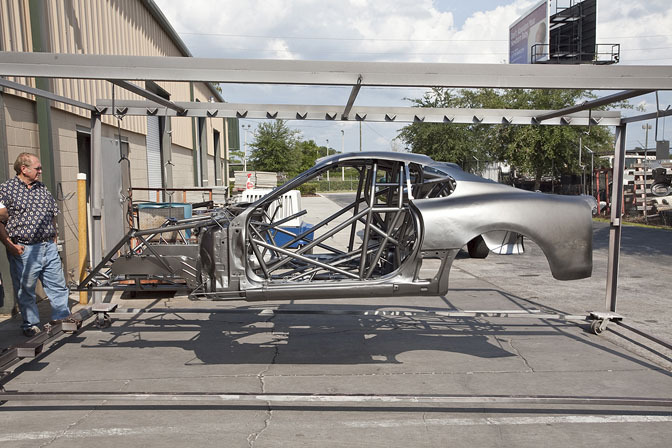

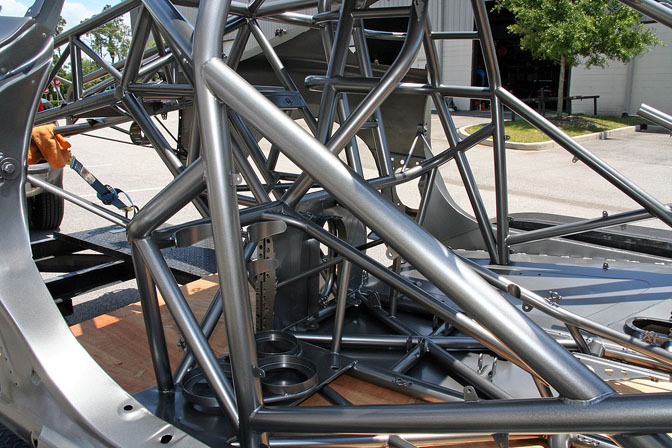

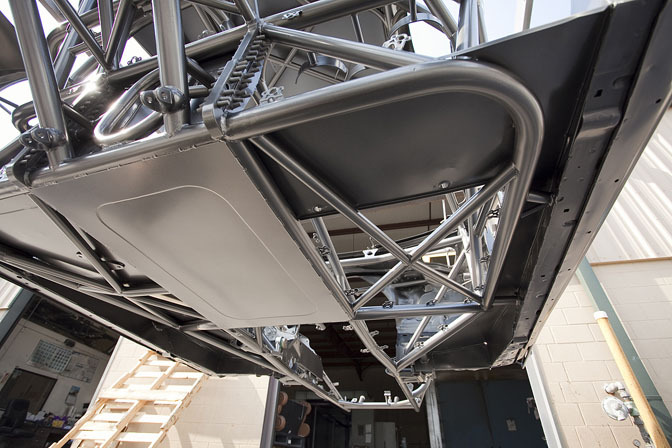

The entire body is hung from a moveable jig, allowing 360 degree preparation and coverage of the inside of the body, as well as chassis structure itself. Prior to coating, the entire surface is acid washed to remove any surface contamination and ensure a good bond for the powder. The car received a coat of electrically charged power while suspended from the jig. Once the entire surface is coated, the chassis is wheeled into a large oven where it is baked, curing the powder to a smooth finish. Once cured, the matte darker color of the powder blends and hardens to the final finish.

The color change in the finish from the above matte powder to the cured final finish is known as thundercloud, which is more of a metallic gunmetal color.

Extreme care was taken to ensure consistent coverage over the entire tube structure and inner body. The coaters spent many hours on their backs under the rig to ensure the powder reached every square inch of the vehicles belly pan.

With the coating of the inside of the vehicle complete, it was time to begin preparing the exterior for its final finish. The car is to be shipped "body in white," with extreme detail taken to ensure consistent gaps, finish work more common if it were a show car rather than a race car.

The factory rear brake ducts would no longer be functional with the huge slicks filling the inner fenders, so we opted to shave them closed. Once molded smooth, these new panels were bonded to the vehicle permanently.

The exhaust routes out the fender in front of the tire on this car, so the rear exhaust hole was shaved smooth.

Once smoothed, the rear bumper was further modified to make way for the parachute mounts.

We also had to modify the bumper further to allow clearance for the wheelie bars. Rather than just cut this area out, we took the extra time to fabricate an aluminum receiver panel, which bonded permanently to the bumper as if it were OEM.

Retaining frames were constructed to mount lexan windows to the lightweight carbon doors. These frames were fabricated out of titanium, including the small laser cut retaining tabs, to keep them as lightweight as possible.

The parachute mount was also fabricated from titanium and holds dual air launched chutes, which can be controlled electronically by the Motec or using a manual pull lever. The chutes also can be deployed using one of the carbon fiber steering wheel paddles, or automatically based on a given set of variables programmed into the Motec – should the vehicle get too far out of shape during a run.

The titanium usage continues with the battery kill switch and tail light mounts fabricated from this lightweight material. While too many these might seem like minuscule items, every ounce adds up to larger weight savings once added up across the vehicle.

The more creative and consistent you are about realizing weight is the enemy, the lighter and quicker the car will end up.

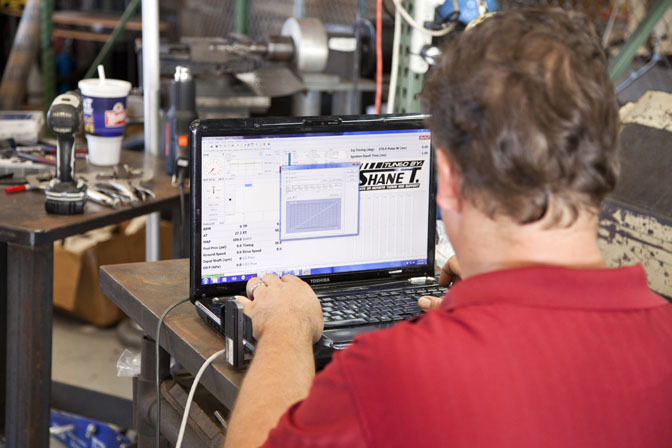

With a vehicle this complex, there was only one person on our radar to handle the electrical and tuning aspects of this job, Shane Tecklenburg. Shane T has tuned many of our most extreme projects over the years and is the exclusive tuner for our production Lamborghini Gallardo twin turbo kits.

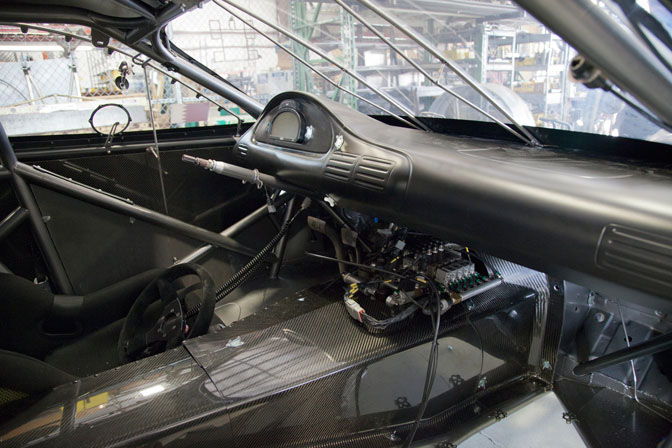

This project allowed Shane to pull out all of the tricks from his hat and use every bit of Motec equipment available. This vehicle has sensors everywhere and is powered by a M800 ECU, SDL3 dash, PDM, and E888.

Here you can see the SDL3 dash mounted to the steering column and how it is flush mounted into the removable dash.

This display has been programmed to include custom instructions, warning lights, and even scroll the owner and project’s name upon start up.

Individual EGT sensors monitor the exhaust gas temperatures for every cylinder, allowing precise data from each run for individual cylinder tuning.

Motec shock travel sensors allow the crew chief to monitor each corner of the vehicles suspension travel during the run and make chassis and vehicle dynamics adjustments using the data.

Producing over 2,000hp out of a six cylinder requires a significant quantity of fuel, and for this particular application we are using methanol. Using methanol has plenty of benefits, but also requires a significant increase in the quantity of fuel required over gasoline. A Hypertune race manifold with (6) Precision 220lb injectors and (6) Moran adjustable injectors (150-600lb) ensure the engine gets all the fuel requested.

A Liberty sequential transmission is complimented with a Motec controlled air shifting module. With this setup the shifts are controlled using preprogrammed variables in the computer, or by pulling one of the Carbon fiber paddles mounted to the steering wheel.

The paddles also make full use of the Motec PDM which allows the same

switch to control multiple parameters. For instance, the right paddle

can be used for the line lock during the burnout, up shifting during a

run, and to pull the parachutes upon a runs completion. The PDMs

electrical circuit replaces any need for a fuse box and allows the

vehicles circuits to be dynamically controlled.

While the vehicles electrical system was being wired and tested by Shane, other members of our staff focused on the finish work. Each piece of the car was inspected, polished, coated and prepared for final vehicle assembly, once the exterior paint was applied. We also had all of the suspension pieces and four link bars mirror polished and nickel coated.

With this project we were building more than just a drag car, but an

entire drag race program. We had to ensure there were proper spares

sent with the car including the engine powering the car as well as two

fully dressed spares.

To make for easy transport, we fabricated engine stands for each of the spare engines. Each stand houses a fully dressed spare power plant complete with manifolds, turbo, fuel system and wiring harness.

The engine features a dry sump oiling system rendering the fill hole and crank case vents on the valve cover useless. Replacement valve covers were made using CNC machined lowers and tops made from lightweight aluminum sheet metal. This not only improves the appearance of the engine bay, but it shaves two pounds over the factory cast covers.

A fresh set of Weld wheels gets wrapped with Mickey Thompson 28 x10.5s, the same tires that have given our Scion the grip needed to achieve three second time slips in 1/8 mile competition.

With the body fabrication and wiring complete, the car was sent to our expert paint and body guy, Brad Samuels. Brad has been painting our vehicles for over 10 years and knows the high level of quality we expect. The powder coated portions of the chassis were wrapped very carefully to protect them from the elements and overspray while at the body shop.

To some, a race cars paint job is not important, however given the quality of this build, we insisted the body and paint be on par with even the best of show cars. Careful consideration was taken to ensure the gaps were tight and all the panels smooth.

Typically race only parts have marginal fitment, so extra time had to be invested to build up edges and correct fitment without adding significant weight.

With all the prep work complete, finish primer was sprayed on the car before a fresh coat of white paint. The car was then color sanded and buffed to an extreme shine before being loaded up for the ride back to our shop for final assembly.

With the body work now completed and a fresh coat of PPG White along multiple coats of clear applied, the car makes the journey back to our shop for final assembly.

In the light, the contrast between the chassis and exterior paint is very apparent. Racing a vehicle puts lots of stress on its finish. Extra care must be taken to ensure it can stand up to the abuse. With the driveshaft, transmission, and various panels being removed and checked after every run, the powder coat must have a good bond.

As you can see by the shine in the exterior paint, Brad Samuels once again exceeded expectations and the results are truly stunning in person.

With the exterior paint job complete, it is time to begin the final assembly of the car. The seat is reinstalled for the last time, along with the CO2 bottles.

These bottles will be used to control triggers for the transmission, the air launched parachute, and wastegates for consistent boost control.

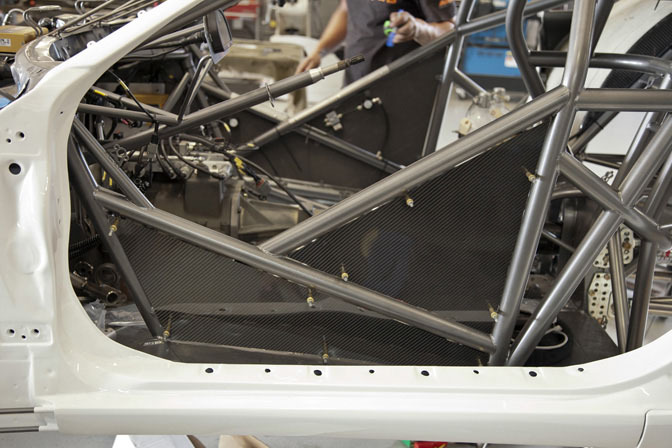

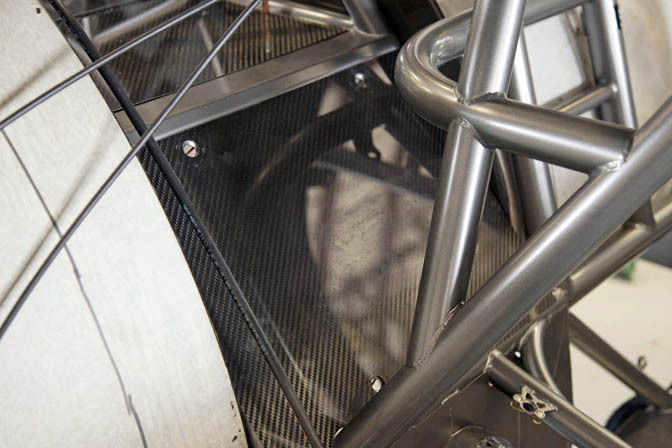

To shed weight and provide for a great looking interior, all of the inside panels will be made from carbon fiber. These pieces all start as raw sheets of carbon fiber, which are template in cardboard then transferred to the final carbon piece. It is a meticulous process of trial and error for each piece, but the end result proves worth the effort.

The wheel tubs are also made out of carbon fiber; these tubs seal the interior from the massive tires and the smoke they create. The tubs must be fitted to the car and still provide ample clearance for the hatch. They are then bonded to the exterior quarter panels to form a tight seal.

Every square inch of the rear is painstakingly trimmed with carbon fiber, each piece cut, fitted and re-fitted to the chassis. It is a very tight and awkward workspace with the tubular structure surrounding at all angles.

Fortunately, once these pieces are in they will be bonded and riveted for a permanent fit.

The lightweight carbon doors were molded based on a factory Supra door, so the center section was cut out to save additional weight; this left a rather large hole, which was covered using a flat carbon trim panel. It is quite amazing how much stiffer the door became just by adding such a thin sheet of carbon to the face.

The transmission tunnel also needed to be fabricated from carbon. The difficulty in creating this piece was compounded by the plethora of shifting solenoids mounted to the top of the transmission which made for limited clearance.

A pro stock dash was fitted to the car, trimmed for the display, and air brushed to create realistic vents. This two-piece dash is designed to be easily removable allowing easy access to the electronics mounted below.

Here is another look at the rear bumper tray now that it has been bonded completely and painted to match the car. If you look closely, you can see the lower wheel tubs have also been fitted to this area, providing clearance for the wheelie bars travel.

With the interior complete, the test engine goes in for the final time. All connections and piping are hooked up and fluids added. Once we have tested the car on the track and ensured everything works as expected, these pieces will be removed for final polished, plating, and coating before the car is shipped to its new home in Bahrain.

We bolt the wheels to the car and lower the air jacks. The car is finally starting to look like a proper race car. From here the windows will be fitted, every last fitting and connection tested, fluids added, and finally the beautiful sound of hearing the engine fire for the first time.

Next post we’ll wrap up the project and enjoy the best part of completing a new car, testing and racing it!

-Titan Motorsports

Titan Motorsports Supra Build Pt.1

Sick ride!

Please do not forget to include a video of the beast for the next post.

Mind blown. Cheers to this no holds barred build, I hope this Supra manages to destroy on the quarter, and never crashes! That would be a shame after all the shaping and detail put into it.

whoow, that's all I got, THIS is a build to be proud of.

fantastic build! some of the best stuff i've seen!

Very nice build

Amazing is an understatement.

Love this series!! Please include a video and e.t./mph with the last installment!

how much extra weight would the paint and final coat add to the weight of the car?

Hey dj, hating ain't gonna get you nowhere

You guys are simply the best; mega like

its a good stuff

Fantastic and intresting build. I just wish i worked at titan now.

finally, was waiting 4 this update on this beast. was worth tha wait, cant wait 2 c a few test run vids

Art !!

awesome. more build threads!

I'm sure it'll be the fastest thing out there, but based on the photos and text, it's a funny car frame under a steel skin, being built to run in a door-slammer class. Everything except the skin and the strut towers was thrown away. The rules may have been written and re-written to allow all of this, but the class is supposed to be for unibody street cars. Hinged doors on a funny car don't make it a door-slammer.

Amazing build, but why no carbon dash?

I still have a question about the titanium-welding. Why do you weld with no "sledge"? It will crack. thats for sure.

Be sure to give us some dyno and test video for the masses.

Wow! What a coincidence!!! I was reading this article and drooling over how amazing and thorough this build is, and it made me think of some friends I went to school with back in Bahrain (members of the very wealthy Bahraini Kanoo family) and how he now races several highly tuned Supras at the Bahrain International Circuit. Next thing I know I get to the end of this article and it says that the car is going to be shipped to Bahrain and immediately I knew it was for Ebrahim Kanoo. Here is a video that shows this car laying a 7 second 1/4, check out his other vids as well: http://www.youtube.com/watch?v=gLgD4kPzf-s&feature=related.

Pretty fucking awesome if you ask me.

Lol. this is a great build, but seriously trying to save 2 pounds is ridiculous. Just have the drive lose those pounds. =p

This Car is the new car of ebrahim kanoo ???

INSANE I want 1

my god that is a beautiful and high quality build

Amazing and awesome! Great post!

there is an entirely straight, perfectly working supra in hacked up peices in the back of Titan motorsports.

Whats OEM still? the door rails? outer skin? You needed a straight body car just for the straight body? most of which is carbon fiber now anyway?

Are you guys going to include the video of when it either A: crashes into a wall in the desert or B: sits in some collection somewhere?

This car is stupid. The owner is a jackass.

Amazing fabrication work... outstanding!

only the fukken BEST!! TITAN MOTORSPORTS!!!!

if this car is build for E Kanoo, not Titans own project i belive the article is dated, but better late than never - the car has done the following times

the IRS supra does 7.59

http://www.youtube.com/watch?v=f7RRPiWVLqo

the 10.5 supra(the one in this article iinm) does 6.76

http://www.youtube.com/watch?v=CeY6u22bFRU

http://www.youtube.com/user/brn996tt/videos

cheers

Talk about polishing a turd.

One question:

Why have fake vents on the dash and fake lights/intercooler on the front?

They could have put a fiberglass tub over the rail frame and they would have had a perfectly good Supra left over as a second car.

Boring.... Its just a money pit car. All this and itll only run 7 down the 1/4. There are full trimmed street driven supras that run 8 and 9's and they contain alot of weight. This to me is just boring and even more so boring as its not even "titans" car its probably kanoo's.

man this is a good year for all out supra builds first chris rado's wild supra now this.

Love these kinds of articles.

I like how the builders are so worried about weight, then they put a sensor at every header outlet and intake inlet. If you are so worried about weight, get rid of every sensor you possibly can, it will run exactly the same, if not better.

omfg so beautiful but y not a TT

@Weasel

They needed a straight body Supra so they wouldn't have to add a lot of useless weight with body filler repairing dents.

@Jay

Titan Motorsports is a tuning shop. They build cars for customers. The only reason they build cars for the shop itself is to demonstrate their potential and attract more customers. So technically E.Kanoo owns the car, but Titan gave birth to the beast. The car wouldn't exist if it weren't for Titan.

I believe with the right driver and minor tweaks, this car will be far into the 6's. You saying this is "Boring" is just plain ignorant. You build a car with 3.4 liters of displacement, put it on 10.5" slicks and see if it will ever get into the 8's, let alone nearly 6's.

I really hope this car doesn't crash. looks great!

With the turbo exposed that way, it looks like the turbine of the Batmobile.

What class will this car be running in? Outlaw 10.5?

To clarify, this project is for E Kanoo racing in Bahrain, however the entire program was built in house at our shop in Orlando, FL complete with spares and shipped overseas. For the first few races our entire crew including driver Gary White will go over and run the car in Bahrain.

The rules stated we had to start with a factory based firewall/frame railed car. The car we started with was not a 100% car but rather one that had some body work and was being parted out when we purchased it.

This car is different from Kanoo's IRS Supra street car which we also provide the majority of the parts and support for, it is currently the quickest IRS Supra on the planet and in a few weeks we hope to further that record. We'll be bringing out Copper Supra out soon enough with a complete revamp in hopes of battling with our customer for top honors and will likely have another post to document that in the coming months.

Thanks for all the support, there will always be a few haters in a crowd but that's expected. If anyone has any specific questions on the project or would like more info on bits and pieces of it my email is wes@titanmotorsports.com and I'd be more than happy to address any questions or concerns.

Lets just say this car will run much quicker than 7s..... more on that the next post (which should be up in a couple of days).

Weasel, late the hate out of your heart - if will only fester inside you and make you even more bitter.

Wes, thanks for the detailed writeup - I look forward to this car continuing to re-write the record books!

Looks like another Titan masterpiece. Lucky for me I live a half hour away. Titan always has some good builds going on. I just want too see Nero head back to Texas and show Underground racing a thing or two.

Wes, you're great guys. Making such a fast RWD car.. Haters of your work simply entered the wrong site it seems, forget it) looking forward to your future projects!

How much does it weigh?

@ A70Slide'r'Die

You being serious man? There are heaps of supras either 3.0 or 3.4 running into the 8's with full trim. Get your facts right. Of course cars wont be born if it wasnt for performance shops because they build them...also if you searched the car already runs it the 6's lol. Plus this is my opinion. I never hated the car all i said is its boring as i prefer full trimmed supras running 8's or 9's.

the car runs 6.7 last month in Bahrain

We're working on something special for Texas, we should have at least one of the Lambos out there, but we're going to save our best for the strip.

As far as this cars weight, I can't disclose the extract figure but it's under 2,850.

Jay, man, no hate but honestly. You do know right? That going from 12 to 10 or 10-8 is easier then go below this? You can't run a full trim car that fast because of weight, a might that would have to compensate the weight will cost a crap load of money with no real reason for that.

And, yes I like street legal cars, fully rebuilt stock cars that still remains original as well. But this has different purpose.

Everything was fine until the story said "the car is shipped to its new home in Bahrain."

I'm usually a huge fan of FD builds, but this is one of the sickest builds with some great coverage of the work and progress. Really impressive work - can't wait for the next installment!

Thanks for sharing!

An old Titan car runs 6.3x.

http://www.youtube.com/watch?v=GaWcS-K55gk&feature=youtube_gdata_player

Here's a shot of Titans old car they sold to Someone in Austrailia. Very impressive.

http://www.youtube.com/watch?v=GaWcS-K55gk&feature=youtube_gdata_player

I see all of the negative comments, but I will say this is a bad ass build! There was a lot of detailed covered. Titan Motorsports is top notch. Also to some of the dumb asses, lets see you put on some 28X10.5's and make some 3 second passes!

the build is nice love how the body of the car came out but this looks more like a show car thean a race car that car is a 3/4 chassis car but really its a full chassi car best of lock with the car n I love that it runs on10.5 tires only real man run 10.5 I