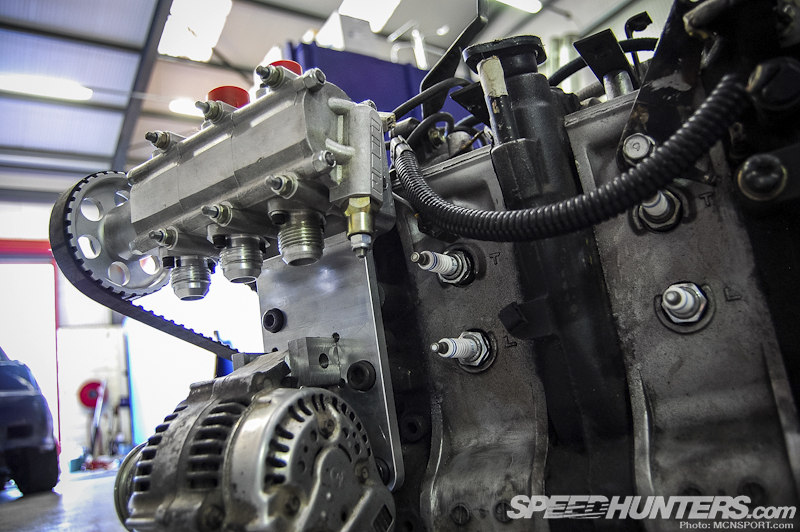

Time for an update on the D-Mac86. We are a bit late with these so we will be bringing you two updates close together. First off a quick update on parts and paint with a new colour for the chassis that I hope you all prefer to the white we used on the 2011 build. Above you can see our new dry sump pump and alternator bracket which will make the engine bay much neater rather than have the top mount alternator like on a stock rotary. We will take a more detailed look at the bracket later…

I have developed a new Skyline brake conversion for the ae86 using 296mm floating front discs and R32GTR rear discs with 4 pot front calipers and 2 pot rears. We will be also fitting alloy front hubs as you can see above. I might get the rears done with alloy bells and floating discs at some stage…

Here is the completed front hub and disc and it really is a thing of beauty. These weigh less than the stock steel hub and disc combined so we have shed a little bit of weight here, and rotating mass more importantly.

Lets take a closer look at the oil pump bracket. We have changed to a 12a front cover using an FC crank sensor as Hayward Rotary supplied the dry sump kit to work with this cover. We are using a the very popular Pace oil pump.

We made sure to allow for enough space to remove the plugs easily as any rotary man will tell you plugs get changed a lot on a 13B. I’m not sure if we will get time to give last year’s motor a fresh lick of paint before Gatebil, but we will def have it done for Silverstone.

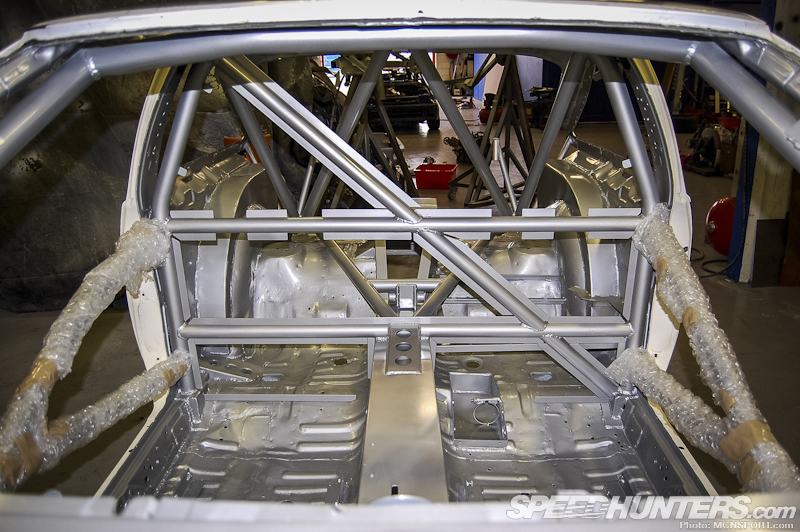

The Chassis is now fully painted in silver this time, which i think is so much better than the white we had before. The silver will work much better with the carbon fibre paneling on the inside this time.

The last job before paint was to cut the front off the chassis legs and plate them, and also to weld on the tabs for the bumper bar.

I can’t wait to get all our new suspension arms fitted to this beast. The new arms will be the first in a range of D-Mac Spec drift specific control arms. Be sure to catch future updates for a look at these.

Here you can see we added strips for the carbon fibre paneling to sit on and separate the cockpit from the ludicrous amounts of Falken Tire smoke.

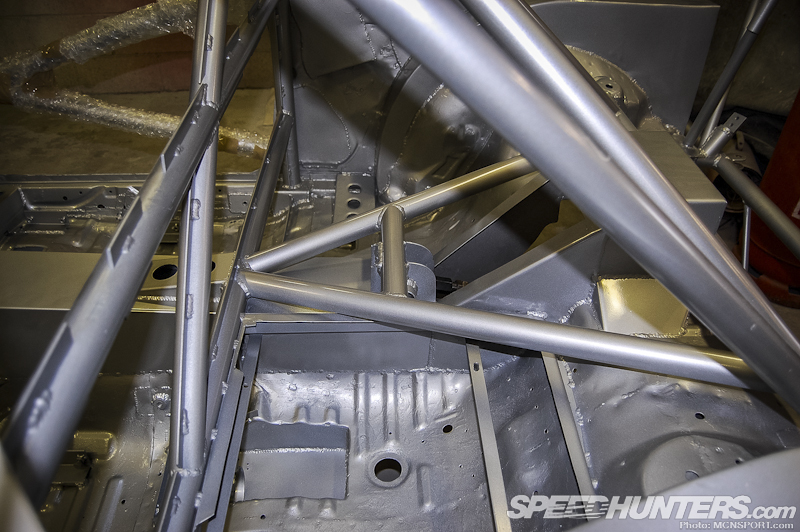

Tunnel vision ![]()

And again… A Saenz Sequential transmission now sits here, so be sure to check our next assembly update.

The car will be slightly heavier than last year, but should have better balance with more weight on the left front and on the rear.

The third link was a problem for us last year, so the mounting has been changed and improved this time around.

Hopefully it will be a very long time before the car is a bare shell again. When we took it apart at the start of this year I never thought it would take so much work for the rebuild. We have gone a step further with everything again to a point where we are using the ultimate in parts and geometry

Even silly things like the half moon rear wheel tubs to get the Falken Tire smoke out the rear as quickly as possible are signs of a very well thought-out design.

I’m really digging the new colour!!

As I write this we are hard at work on the dry sump lines, rear axle shock mounts, fuel system, exhaust etc etc. I felt this time around it was important to have as many bolt-on parts as possible on this car.

So items like our D-Mac/AVO suspension is the same as we sell all over the world to our customers, and i think it is important to show just what they are capable of.

Our D-Mac spec front suspension arm system is also nearly ready and will be one of the key components to unlocking the potential in this car, and again these are all straight bolt-on parts that will fit any AE86. We feel like we have really perfected the design this time and we are hoping for a much more competitive car in 2012.

Now time to get back to work

Another update is coming very shortly!

-Darren ‘D-Mac’ McNamara

simply amazing i love fabrication

I´m sorry but those welds look kinda sketchy. Surely a man with those kinds of fabrication skills can do better. MIG-welds CAN also be nice to look at and very strong at the same time, don´t need a TIG for that.

Otherwise a great car!

@Priit True, they aren't the neatest welds in the world, but I think this is an example of function over form. Dmac and his team probably have very little time to build this awesome machine, and therefore focus on the more important parts of the fab work.

For such a high level car, why not spend a bit more time on neater fab work, by the looks of the welds the joins in the bar work are fairly gappy,

the silver is a nice change! I'm liking the gtr rotors, I've got some ae86 struts on one of my cars and would like to see more on the setup.

Also, I have to agree with what has been said of the cage welds, particularly the crossbar. I'm assuming it's DOM tubing because it's been MIG'd, but some of them look too cold, lacking penetration.

"..any rotary man will tell you plugs get changed a lot on a 13B." How often? Once a month? Once a race? Sorry. Rotary-man-in-the-making here.

@westhave A good looking weld is generally a strong weld, you dont weld nicely for form. Not trying to be negative here but I agree they could be better, regardless of timeframe. Do it once, do it right.

@westhave A good looking weld is generally a strong weld, you dont weld nicely for form. Not trying to be negative here but I agree they could be better, regardless of timeframe. Do it once, do it right.

@westhave A good looking weld is generally a strong weld, you dont weld nicely for form. Not trying to be negative here but I agree they could be better, regardless of timeframe. Do it once, do it right.

@westhave A good looking weld is generally a strong weld, you dont weld nicely for form. Not trying to be negative here but I agree they could be better, regardless of timeframe. Do it once, do it right.

@westhave A good looking weld is generally a strong weld, you dont weld nicely for form. Not trying to be negative here but I agree they could be better, regardless of timeframe. Do it once, do it right.

I really don't understand kids these days... always searching for flaws - something to tear apart. If no flaw is found, they flip from mock to worship. gods n clods.

I really don't understand kids these days... always searching for flaws - something to tear apart. If no flaw is found, they flip from mock to worship. gods n clods.

I really don't understand kids these days... always searching for flaws - something to tear apart. If no flaw is found, they flip from mock to worship. gods n clods.

I really don't understand kids these days... always searching for flaws - something to tear apart. If no flaw is found, they flip from mock to worship. gods n clods.

I really don't understand kids these days... always searching for flaws - something to tear apart. If no flaw is found, they flip from mock to worship. gods n clods.

Silver is badass. VERY nice build. The reason some people pick it apart is so that other people can learn. For example, it appears that the rules allow you to penetrate the firewall with your tube cage, as seen by the tubes running from the dash area out by the fender forward to the front strut / shock towers. I'm surprised that the constructor didn't triangulate the front end more. Perhaps there are clearance issues, but it's a good idea to run tubes from each shock tower which meet in the centerline of the car and tie into the dash bar. This will help provide support, especially in a lateral direction like a "strut tower bar" does. This of course means 2 more penetrations through the firewall, which might not be allowed by the rules.Along the same vein I'm surprised they chose only 1 diagonal member in the center of the car.

In any case, considering the quality of what they have already accomplished in these photos, I doubt the performance difference would be much. This thing is damned good. I'd like to see this beast in the hands of The Drift King!

Silver is badass. VERY nice build. The reason some people pick it apart is so that other people can learn. For example, it appears that the rules allow you to penetrate the firewall with your tube cage, as seen by the tubes running from the dash area out by the fender forward to the front strut / shock towers. I'm surprised that the constructor didn't triangulate the front end more. Perhaps there are clearance issues, but it's a good idea to run tubes from each shock tower which meet in the centerline of the car and tie into the dash bar. This will help provide support, especially in a lateral direction like a "strut tower bar" does. This of course means 2 more penetrations through the firewall, which might not be allowed by the rules.Along the same vein I'm surprised they chose only 1 diagonal member in the center of the car.

In any case, considering the quality of what they have already accomplished in these photos, I doubt the performance difference would be much. This thing is damned good. I'd like to see this beast in the hands of The Drift King!

Silver is badass. VERY nice build. The reason some people pick it apart is so that other people can learn. For example, it appears that the rules allow you to penetrate the firewall with your tube cage, as seen by the tubes running from the dash area out by the fender forward to the front strut / shock towers. I'm surprised that the constructor didn't triangulate the front end more. Perhaps there are clearance issues, but it's a good idea to run tubes from each shock tower which meet in the centerline of the car and tie into the dash bar. This will help provide support, especially in a lateral direction like a "strut tower bar" does. This of course means 2 more penetrations through the firewall, which might not be allowed by the rules.Along the same vein I'm surprised they chose only 1 diagonal member in the center of the car.

In any case, considering the quality of what they have already accomplished in these photos, I doubt the performance difference would be much. This thing is damned good. I'd like to see this beast in the hands of The Drift King!

Silver is badass. VERY nice build. The reason some people pick it apart is so that other people can learn. For example, it appears that the rules allow you to penetrate the firewall with your tube cage, as seen by the tubes running from the dash area out by the fender forward to the front strut / shock towers. I'm surprised that the constructor didn't triangulate the front end more. Perhaps there are clearance issues, but it's a good idea to run tubes from each shock tower which meet in the centerline of the car and tie into the dash bar. This will help provide support, especially in a lateral direction like a "strut tower bar" does. This of course means 2 more penetrations through the firewall, which might not be allowed by the rules.Along the same vein I'm surprised they chose only 1 diagonal member in the center of the car.

In any case, considering the quality of what they have already accomplished in these photos, I doubt the performance difference would be much. This thing is damned good. I'd like to see this beast in the hands of The Drift King!

Silver is badass. VERY nice build. The reason some people pick it apart is so that other people can learn. For example, it appears that the rules allow you to penetrate the firewall with your tube cage, as seen by the tubes running from the dash area out by the fender forward to the front strut / shock towers. I'm surprised that the constructor didn't triangulate the front end more. Perhaps there are clearance issues, but it's a good idea to run tubes from each shock tower which meet in the centerline of the car and tie into the dash bar. This will help provide support, especially in a lateral direction like a "strut tower bar" does. This of course means 2 more penetrations through the firewall, which might not be allowed by the rules.Along the same vein I'm surprised they chose only 1 diagonal member in the center of the car.

In any case, considering the quality of what they have already accomplished in these photos, I doubt the performance difference would be much. This thing is damned good. I'd like to see this beast in the hands of The Drift King!

@dr dre

Charity has little to do with the nitpicking on here. People just want to sound smart. The welds are just fine, for a drift machine that will be yanked apart again in a year.

Wow so much more professio

I'm tired of you guys complaining about these welds, and the design here and there. Go out and build a car to this level and you will see how hard it is.

@Bosae86

Crappy welds on a rollcage equals severe injury or death. Welds are what hold the car together. There's no way that a car with those kinds of welds could ever be allowed on a rally or rallycross event. Believe me, I know. Not being a hater, just weird seeing such welds on such a high level car. Nothing wrong about the car otherwise, I think it's a great piece of engineering and fabricaton.

@SPEEDHUNTERS Luv the blog updates for #Dmac86! All the amazing hard work & time will pay off. Can't wait 2 c it run. Almost there! @dmac86

Thanks for the comments everyone. I guess i better comment on the welds.... i might not be the best welder in the world but i like to do as much of the work as possible myself. I am still learning as a fabricator and driver so i'd rather learn than get someone else to do it

We change the plugs once a race

I cannot find a picture in this collection where it is clear without a doubt to condemn his welds on the cage. Not clear enough to see if they are too cold, if there is undercut, etc. Just because a weld is pretty doesn't necessarily mean it is strong. There are plenty of weak pretty welds out there. A down hill weld is a perfect example of a really pretty, cold, ill-penetrating weld that would easily crack and break.

don't apologize to critics and fools...

It is not the critic who counts; not the man who points out how the strong man stumbles, or where the doer of deeds could have done them better. The credit belongs to the man who is actually in the arena, whose face is marred by dust and sweat and blood; who strives valiantly; who errs, who comes short again and again, because there is no effort without error and shortcoming; but who does actually strive to do the deeds; who knows great enthusiasms, the great devotions; who spends himself in a worthy cause; who at the best knows in the end the triumph of high achievement, and who at the worst, if he fails, at least fails while daring greatly, so that his place shall never be with those cold and timid souls who neither know victory nor defeat.

welds are mig. thats what mig welds look like. get over it