Hey, Speedhunters! Time for another update on the 86. The excitement is really starting to build and the finish line is in sight. As we are leaving the outside the same colour as last year all the panels just need to be re-fitted once the chassis is complete. It doesn’t look much like a car right now, but the exterior will come together very quickly.

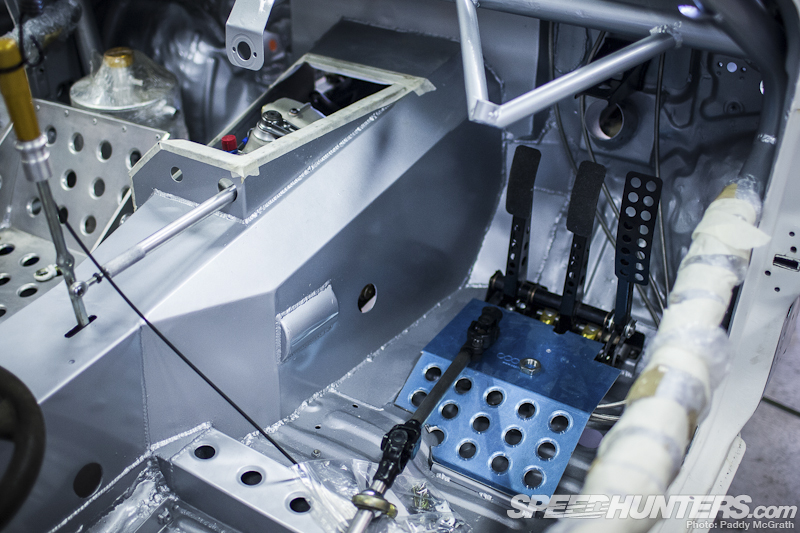

Paddy called while I was in New Jersey for Formula Drift so it’s good to have proof that the boys were busy while I was away haha. There is a lot going on in this photo… I see an OBP floor mounted pedal box, OBP dry sump tank, passenger footrest and the top of out Saenz sequential gearbox. Mmmmm…

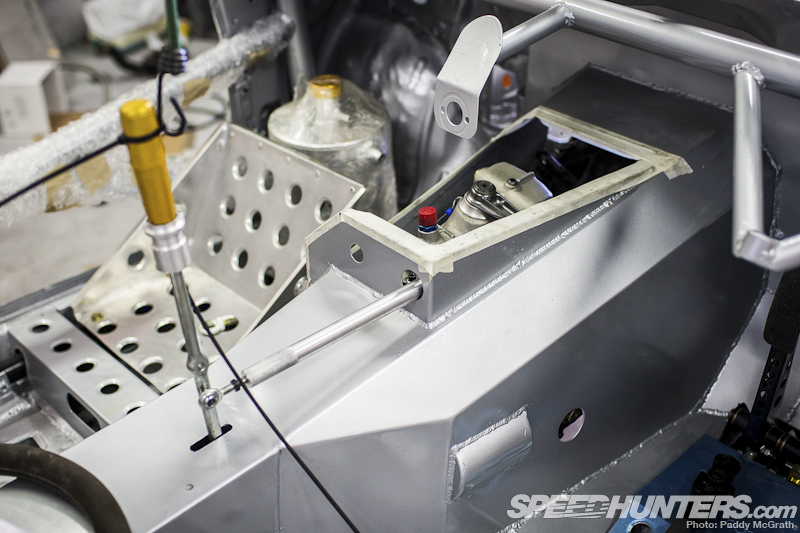

The axle is now in place so the third link is bolted in. It is adjustable from inside the car, which will make setup changes easier. We are also mocking up the fuel cell at the moment…

…as you can see in more detail here.

The rear mounted radiator mounts in the same position as last year.

But the adjustable panhard rod mounts are new for 2012.

Back inside the cockpit, our gear selector rod is a little short so we are machining up another one.

Here is the Saenz unit. It really is engineering porn at its finest. The engine and gearbox have to come out one more time, and I’ll be sure to get a pic for you of the unit sitting on the shop floor.

Hmmmm, I wonder how many of these will be left over when the car is finished. Then you have that moment where you second guess yourself and think you’ve forgotten something.

Our Owen Developments turbo has a new location this year with a much shorter Martelius custom manifold to increase response. You can also see the flange for the external wastegate hanging down here. Everything is much more compact this year, and mounted lower.

We also sent the turbo and inlet manifolds to Martelius Exhausts in Finland to get ceramic coated. I was really impressed with the ceramic coatings we did last year and now we have taken it to the next level with the whole exhaust system, turbo, coolant pipes and inlet manifold being coated.

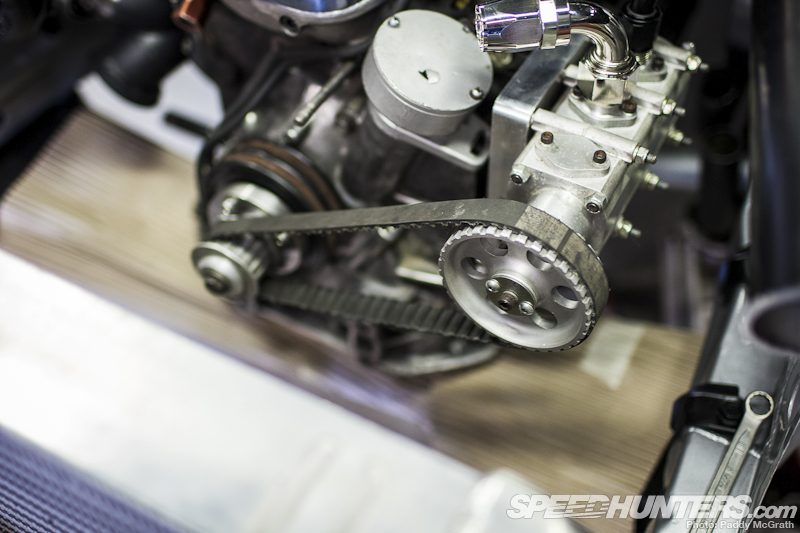

We have deleted the old water pump assembly and replaced it with a much neater system. The two coolant pipes will run down behind the oil pump on their way to the radiator.

As I write this, I have just received a new dry sump belt to replace this worn old one and we have most of the -12 oil line plumbing done.

A place for everything and everything in its place……well kinda.

This shot really gives an idea of how much work has gone into this chassis. Almost no area is without modification. If this wasn’t already, it is now surely the world’s most extreme AE86.

I like how the dimpled holes on the passengers footrest line up with the dimpled holes on the seat crossmember. I cant get enough of looking at that gearbox!!

It’s certainly a beehive of activity at MCNSPORT at the moment. The shop will get a nice break once we leave for Gatebil in two weeks. Still so much to do to the car though, and at the same time we have got to be further ahead than Fredric, who doesn’t have a 1,600 mile drive to get there…..

The intercooler and oil cooler are ready to be mounted in this picture. Another advantage of the rear mounted radiator is the very low intake and oil temps we are getting, meaning we do not have to carry so much oil. Our new OBP oil tank is only 1.5 liters.

The two pipes in the middle of this shot are the new coolant pipes from the engine to under the chassis. They are quite complex and run under the throttle body, but allow us to run the two coolant temp sensors without them being visible.

Here is “Happy” Darren fabbing up the intercooler brackets. Watch that fresh paintwork!!

Here you can see one of the coolant pipes running under the passenger footrest. Martelius coated these with a thermal dispersant or a thermal insulator depending on whether it’s the hot or cold pie from the radiator.

So the work continues into the night everyday at MCNSPORT….

In the next update we should have the D-Mac Spec arms to show you and hopefully the rear axle will be fitted along with the driveshaft. We should be ready to get this thing back on the ground . The engine and gearbox will be removed one last time and re-fitted with the new sump pan etc. All bolts will then be tightened for the final time.

Until next time…

-Darren ‘D-Mac’ McNamara

Photos by Paddy McGrath

I love these post, keep em coming!

Great pictures! Love all the sheet metal work, TOP notch stuff.

I hate to beat on a dead horse, but those welds look iffy! As long as you feel safe in there.

liiiike

You're not worried about hot coolant likes INSIDE the cabin?

And "likes" == "leaks" ofcourse.

Keep it up! I've always been a big fan of a third link inside the cabin of a car! But the real question is...20b for 2013???

That nuts and bolts surely is a fuss. How did you guys know which is the right one for the right part?

Thanks for the comments. We ran the coolant lines in the car last year with no problems and it very easy to make them leak free. Internal coolant lines is very popular with rear mounted radiators.

After a while working on the car you get to know which bolt goes where

@DMac86 hey man, just wanted to say how good it is to see you putting so much work into your own chassis. this is so much like the way of life of my best friend and i. few people can understand the depth of the relationship it creates with your car. i would be honored if you could check us out on facebook, im JasonMother FuccinRichards.our page is illuminati, if you ever have time lol, just wanted to say thanks for letting us in on the progress, and cant wait to see you giving this thing hell!

i LOVE that last picture. i feel like it captures the moment so well..

great!!!

great!!!

I would like to thank you for the efforts you have made in writing this article. I am hoping the same best work from you in the future as well. In fact your creative writing abilities has inspired me.

I would like to thank you for the efforts you have made in writing this article. I am hoping the same best work from you in the future as well. In fact your creative writing abilities has inspired me.

I've really enjoyed reading your different articles. They are so informative and interesting.

I've really enjoyed reading your different articles. They are so informative and interesting.

I think this is an informative post and it is very useful and knowledgeable, great tool. I would like to thank you for the efforts you have made in writing this article.

I am very happy to read this. This is the kind of info that needs to be given and not the random misinformation that's at the other blogs. Appreciate your sharing this best post.