Part three of the 86-X build story ended with me arriving in New Jersey for Formula Drift Round 4. By qualifying in third we started off the event strong, but with the help of a drivetrain failure in the final turn of our Top 16 battles we ended our competition weekend early.

JTP was super fast, as always, but we felt that we were putting in some strong performances too!

I also got to do some double donuts with Matt after a Top 16 absence in Palm Beach for both of us. Erica Nagashima from the Hankook camp shot this quick sequence during the drivers introduction.

Flying back to Norway this past Monday, I was very eager to get to work on the 86-X. I wouldn’t recommend bringing 100 kgs of parts (including a 2JZ stroker crankshaft) as your checked baggage, but sometimes you got to do what you got to do.

Just as I got back to Norway, I jumped in my van and cruised away deep into the woods, headed for the Swedish border. Joe Harry Linnerud literally has one foot in Norway and one in Sweden as he walks across his front yard. He had been hard at work building the cage, the rear firewall, the radiator mounts and the front crash bar while I was away.

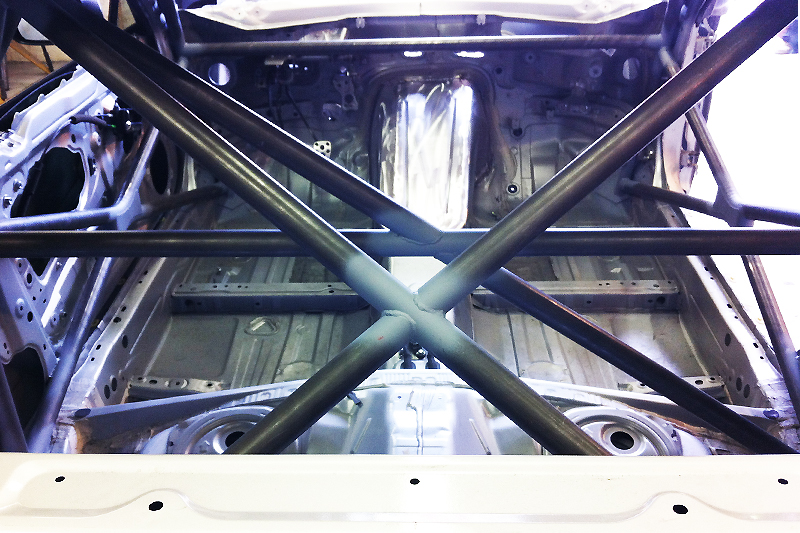

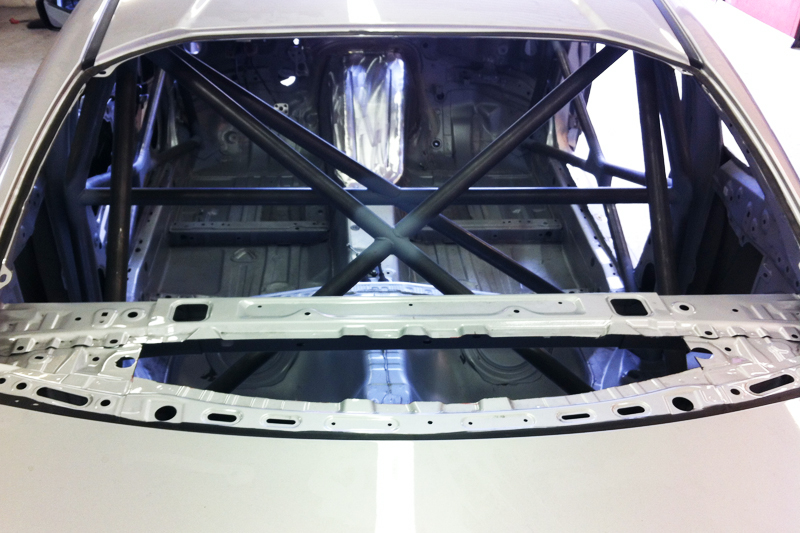

I was very eager to check out his work, and here it is. Please excuse my poor phone snaps!

The fab work had come out absolutely amazing!

Linnerud had tied up the front hoops to the A-pillars with gussets. Because of the FD rules, which state that you are only allowed to have two bends for each front side hoop, there will be gaps between the A-pillar and the cage.

For the B-pillars, however, the cage was welded directly to the door shut seams and the roof liner. That’s how tight the cage came out!

I had requested to have the main hoop set as far back as possible, just about where it starts to limit my head room due to the front hoops and the angularity of the roof. Not only does it reek of RACECAR when the main hoop is visible in the rear side windows, but the further back you put it, the more room and flexibility for the driver seat position you’re going to get.

Joe Harry included horizontal and diagonal main hoop cross bars as per the Formula Drift regulations. The horizontal bar also functions as seat belt top mounts. In addition, he made an extra cross in-between the rear shock tower bars to stiffen up the unibody structure. This should help prevent chassis distortion in serious hits to the rear. Yes, I am talking about those outer clipping zone incidents that definitely do happen…

We will be doing a rear mount radiator setup in this car and we are planning some trickery to make the install as simple to build and maintain as possible. The rear window parcel shelf cutout, as you can see in this picture, is part of this setup. We are aiming at bringing air in through the radiator from the bottom of the rear window, and then have the hot air exit through large openings in the rear hatch.

What we are trying to do definitely contradicts a few aero guidelines, but we don’t care about conventions too much anyway. That said, some good input on this is definitely appreciated! We are hoping that there won’t be too much turbulence down by the hatch and radiator air intake because of the sleek curves of the rear window.

This is how the radiator will be sitting. Linnerud cut out the frame rails behind the rearward most subframe mounting points and made pockets that house the radiator firmly. Some upper mounts that tie the radiator down will be put in place, and we will retain access to the filler cap as well as the water inlet and outlet.

Linnerud has been doing an amazing job with the car! It’s been so inspiring to work with him, not only because of his fabrication and design skills, but also because of how he has grasped what this project is all about.

The real key to being able to pull off a race car build in a month is to keep your head straight. It is incredibly easy to get tempted to go down the side route of doing just a little bit more and fabricate things just a little bit better than what is actually needed. If you are down to work with such a tight time frame, you need to “kill your babies”.

By that, I mean that you need to skip all of the “this would be nice” extras. You will have to make things in a quick, straightforward way, and many times you will have to use standard OEM parts. And wherever you can’t get away with OEM stuff, you need to work with companies that understand the project and can get you parts that are actual bolt-ons for your specific application.

Like these KW Suspensions 3-way adjustable race coilovers. This is KW’s most badass setup, with separate low and high speed compression, plus rebound adjustability. This particular kit is one of their very first setups that are tailored to the GT86/FR-S in terms of shock body lengths, bracketry, top hats and bottom mounts as well as spring selection and valving. We run this same style setup on the tC, and the KW products and support have been instrumental in dialing in much needed speed into a car that started out as something very different from a pro drift car.

I can’t wait to test these out on the 86-X!

Another bolt on example is the WP Pro Brakes setup that just shipped out of Taipei. Designed in Canada and based off of a mix of data input from our friends over at Greddy USA as well as visual identification of production 86 parts, this is their very first complete brake setup for the new Toyota sports car.

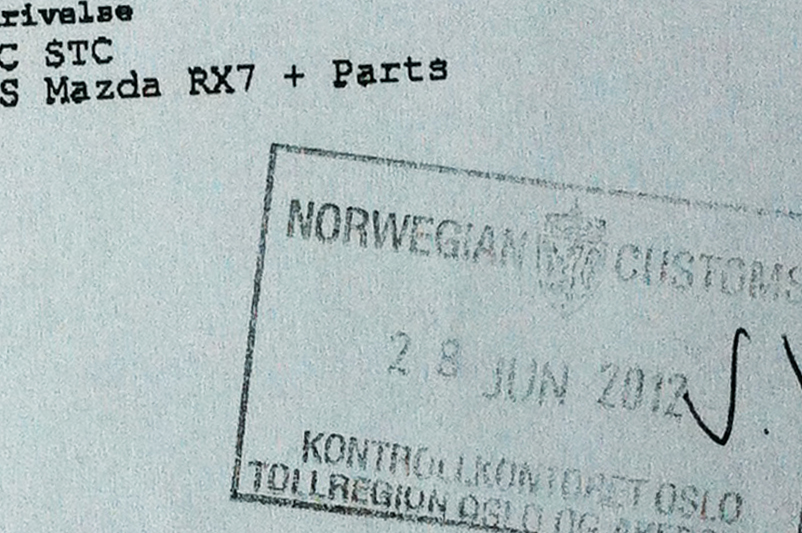

I will leave you with this final shot for now. This is a customs clearance stamp from one of the small access ports of Norway. As you can see, it states that a certain Mazda RX7, shipped out of Auckland, New Zealand, is soon to show up in Norway… Just in time for Gatebil.

All I can say at this point, is that July is shaping up to be full crazy in every respect. We have less than two weeks left, and the countdown has begun!

It’s time to hold stumt.

Fredric

http://www.facebook.com/OfficialFredricAasbo

The Speedhunters Toyota 86-X project is made possible thanks to the support from our partners:

Its not uncommon to have the air intake to the radiator through the rear side windows.

No extra charges for the extra luggage? Haha. Anyway, I cant wait to see how it look on Rocket Bunny! All the best!

@MatsNorway Yep, but the rear side windows on this car are pretty small and would probably only accomodate one typical 3-inch NACA duct, which likely wouldn't be enough. That's why we are trying to pull air from the bottom of the rear window instead. We will add more ducting if needed.

Correct my please if I am wrong, but I thought the Diagonal Down Bar behind the driver must one piece and the horizontal bar which the harness shoulder straps are tied needed to be two-pieces.

Correct my please if I am wrong, but I thought the Diagonal Down Bar behind the driver must one piece and the horizontal bar which the harness shoulder straps are tied needed to be two-pieces.

@Aaron Shaw Aaron you are right, the diagonal bar coming down from behind the driver's head to the passenger's B-pillar "corner" should be one piece.

And the bar horizontal to the floor that connects the b-pillar should be split in a half. That design is much stronger and safer in case of a serious accident, but who knows.....it's only FD, how can you take things seriously with FD and it's rules. They constantly bent the rules to accommodate whoever they want....(another reason why I don't follow/ care about FD).

@Aaron Shaw Aaron you are right, the diagonal bar coming down from behind the driver's head to the passenger's B-pillar "corner" should be one piece.

And the bar horizontal to the floor that connects the b-pillar should be split in a half. That design is much stronger and safer in case of a serious accident, but who knows.....it's only FD, how can you take things seriously with FD and it's rules. They constantly bent the rules to accommodate whoever they want....(another reason why I don't follow/ care about FD).

I am forever confusing this build with the DMAX 86. The other night/early morning i was looking at the dry sump oil pump for the DMAX 86 and was thinking, "What the hell thats a funny looking 2JZ??".

Build is coming along nicely can't wait to see this competing.

I am forever confusing this build with the DMAX 86. The other night/early morning i was looking at the dry sump oil pump for the DMAX 86 and was thinking, "What the hell thats a funny looking 2JZ??".

Build is coming along nicely can't wait to see this competing.

Can the radiator not be mounted underneath the car? Under the boot floor? I imagine it would be a lot easier directing air to an from. Kinda like when fitting a Subaru engine into a VW.

Can the radiator not be mounted underneath the car? Under the boot floor? I imagine it would be a lot easier directing air to an from. Kinda like when fitting a Subaru engine into a VW.

@JDMized @Aaron The rules state that one of the bars has to be one piece, but you can choose which one.

@JDMized @Aaron The rules state that one of the bars has to be one piece, but you can choose which one.

@FredricAasbo i was told by fd tech that if my door bars didnt actually "intersect" then i need two vertical bars. i build these same door bars and i was told i needed verticals because they dont actually intersect wtf??? awesome work aasbo!!

@FredricAasbo i was told by fd tech that if my door bars didnt actually "intersect" then i need two vertical bars. i build these same door bars and i was told i needed verticals because they dont actually intersect wtf??? awesome work aasbo!!

let me worry about that stuff

let me worry about that stuff

let me worry about that stuff

-fida

im guessing the rx-7 is going to b mad mikes d1nz car??

if so got 2 love that na quad rota!!!

@FredricAasbo @MatsNorway The bottom of the rear window generally is a high pressure area, but for a car that spends most of its time sideway, my estimation is that a bunch of vortexes is all you would get. I think pull the air from the rear fender like rallycross cars would better suit this application.

Freddy it might seem like a pain in the ass for the air ducts, but why not cut through the top of the shoulders of the car, air is most definitely going to pass through there, and it's just a little behind the rear/small window so I'm sure there would be plenty of air to feed the radiator. It would make sense as well since you'll be going mostly sideways... However you guys decide to do it, I can't wait to see the final result. Will you be running a Garrett turbo? Are you going to do a Daigo and put the oil cooler in the back as well?

@illuminati @FredricAasbo

That's what I said! FD, it's judges, and tech are a joke! A circus run by clowns. Depending with whom you talk to, you'll get a different answer.

Like I stated above, the perpendicular bar going down behind the driver's head should be one piece, whereas the bar for the harness attachment should be split.

Ask any legit tech folks for NASA/ SCCA, they'll all give you the same answer.

@JDMized @illuminati @FredricAasbo agreed.!

@JDMized

just read the rule book, it is very clear.

G yeah : 13B rotary in the 86 !!!!

Gott med stress mek!!