Cars built by Fluid Motor Union have graced these pages before, including this BMW E90 M3 that I featured in November last year. The other day I got an email with an update regarding this car. FMU engineered a new velocity stack system for the car and when I looked at the shots my jaw dropped.

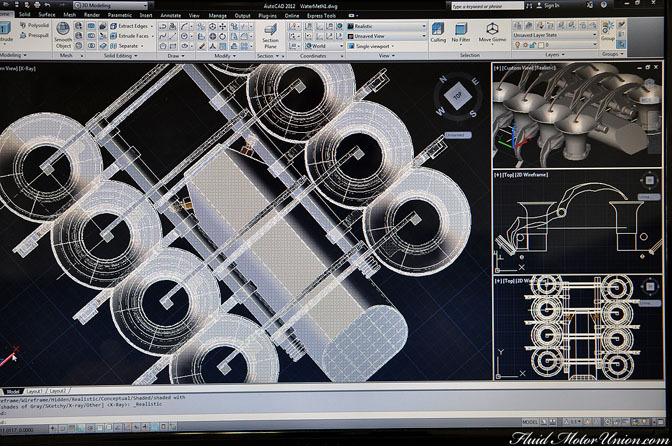

The velocity stack has been designed and engineered in-house using AutoCAD.

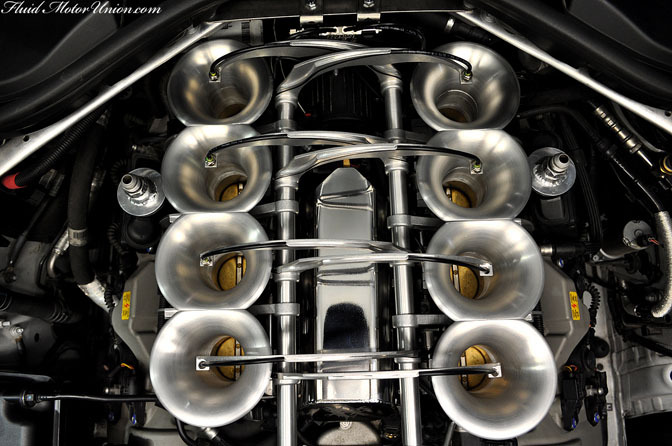

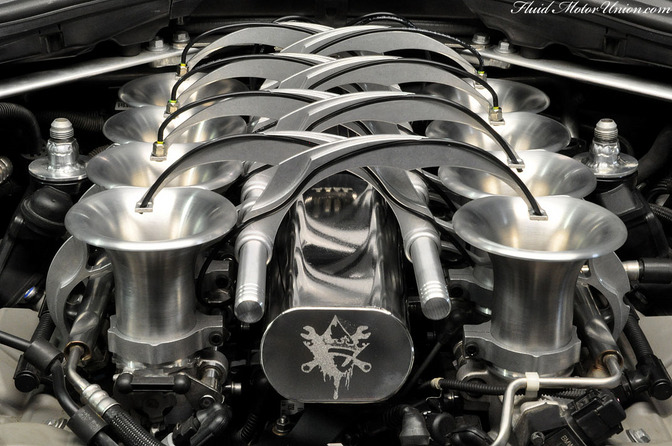

The end result are these beautifully sculpted aluminum stacks and arms.

It's not completely finished just yet but already it has so much potential. I would drive the car without a hood if I had something like this to show off!

I'll let Mike from Fluid Motor Union explain what we are looking at here.

"The system incorporates an Aquamist water-methanol injection system, which runs from the tank in the back to a specially-designed manifold that splits up the 6mm inlet to eight 4mm direct-injection nozzles, which are placed at the ends of the arms that stretch over each individual stack."

I can't wait to hear this setup being put through its paces on the dyno or the street.

-Jeroen Willemsen

Overkill is a beautiful thing.

Video should be getting shot as soon as everything is put back together. All the nozzles are in now, too, so we're ready to rock and roll.

Thanks, Jeroen, for your piece! Keep up the good work

Meth on a N/A motor?

Isn't the same configuration used in f1 motors?

beautifull work

^ It's all about the knock control. The E9x M3's adaptive knock control uses an advanced form that measures ionic resistance of the gap in the spark plug inside the cylinder. This system originated with the E60 M5, and when it came out it was the most advanced form of knock control this side of F1.

While our owner/founder was taking his E60 M5 introduction class as part of his factory training, he theorized that the advanced knock control would continue to advance timing and make power, so long as the octane rating was high enough. This was the main reason behind our decision to run water-meth on the N/A S65B40 (which is based off the E60 M5's S85B50). We feel that as long as the adaptive knock control can keep pushing timing with a higher octane from the water-meth, we'll keep trying to pull power from that. In the years since that factory training, we've kept working with water-meth on N/A systems to see if his theorizing was correct, and we haven't hit any trip-ups as of now.

Obviously, risks are inherent. We understand that.

As a mechanical engineer I approve.. this is one sick set-up, and throttle response must be telepathic. Great Stuff!!

looks gorgeous, even for something that would hard be seen by most people, the attention to detail is incredible.

Just one word: Beautiful!

WOW

Loving this

Desktop of #4 or I am boycotting this site forever!

that is sweet, they must put a video on the net soon, i would love to hear that thing

They could have cut a channel in the bottom of the arms and hidden the meth lines in there... that would have been really cool. I want to see a video regardless

Wow! to say this is a work of art is no exaggeration. It's beautiful and the fact that it's not just for looks makes it even more beautiful.

Ockham couldn't have said it any better.

That thing is friggin badass! That's all I have to say

would look awsome with brushed aluminum valve covers an some carbon fiber details around the engine bay

Is there no air filters then?

Love it

I love that the companies of a featured car have taken the time to write back so we can learn more. Also, I'll add voice to the 'We want wallpapers' and 'We want video/audio' camps.

Engineering is art sometimes

How difficult will it be to supply large amounts of cool air into those horns with the hood on? I've seen similar setups (though nothing as stunningly beautiful), and most were open hood, or at least had a huge blower scoop above them.

so now I know what to start working on in solidworks next ....

can this system run completely on methanol??

That is absolutely beautiful!

pretty sure Saab has been using this form of adaptive knock control for a long time, well before the E60 M5. The DIC cassette is a coil-on-plug unit and knock sensor.

Just sayin =)

Fluid motor dude , please upload a video in order to check the sound of the beast!

Isnt autocad for civil engineering?

Years ago I designed an aluminum cylinder head for Ford Sierra Cosworth using AutoCad ... the best and the worst program in the world.

they should run a clear hood to show the engine bay of easily

itb m3 ???.....

Wow! Just awesome guys.

That's a work of art indeed.

I'm wondering, can you put filters on those? As sexy as those stand-off injectors look, letting anything go inside may hurt the engine in the long run...

Additional pics @ http://www.6speedonline.com/forums/bmw-m/248217-fluid-motorunion-all-new-e9x-velocity-stack-system.html

from what im gathering it only shoots meth out of the runners over the itbs? if so wheres the fuel injected if im wrong its a TBI setup? im guessing crazy high compression ratios are the goal with a wild rev limit idk what im looking at

As a Machine engineer student i must say this looks very professional and precise built.

Very good ! A+

Videos coming early next week! I'll be filming today! Check either StanceWorks' forums or our website's blog for the vids once they're up! I'll pop some links back to here, too! Thanks for all the kind words, guys.

And for the record, we don't run filters because we choose not to. We know the risks, and while we're not saying we know better than BMW's engineers ('cause we don't), we know what's worked for us in the past, so we'll keep following along with that.

Plus, injecting water-meth into a filter is notsogood

that set up is dope. didnt expect to see such a work of art. wow i bet you made the other m3 guys jealous. lol. can you imagine going to bimmer fest with that set up.

Meth injection is a lie!

MEOW FO SHO

I want more of this....... YES

What are you using for the ignition advancement control, and have you seen a limit to the amount of advancement that the DME can add (assuming you use the stock DME) Have you seen any draw backs or any obstacles to this setup? I'm currently enrolled in the S65 class for BMW STEP.

Oh man, just to moved to Chicago a few months ago in my E38. Then just found out last night that FMU were in the suburbs of here (after following their S62-powered E38 for a couple years). Planning on visiting them sometime this week.

Absolutely gorgeous.

Mmmm, very lush indeed. All i can see though, are those little thin aluminum arms getting metal fatigue from vibration and then cracking and going through the engine. If its the right grade of alloy it should be ok though, and oh thats right-its a bmw, they run really smooth dont they?