Here is a quick update for you guys on the Need for Speed D-Mac '86. Our mock up exhaust manifold has been sent to Martelius exhausts in Finland along with our front and rear coolant pipes to be ceramic coated. Here is a shot of the new Martelius manifold being welded in Finland.

And here is the finished product. I think you'll agree they have done a great job and the new manifold will be at MCNSPORT HQ very shortly for final fitment.

As mentioned above Martelius offer a ceramic coating service. The two treatments we will be using on the D-Mac '86 are a 'Thermal Barrier' and a 'dispersant'. The manifold and eventually the turbine housing of the Owens Developments turbo will be coated with the 'Thermal Barrier' which not only lowers the under bonnet temperatures but also prevents the loss of energy from the exhaust gases to the manifold and housing through heat absorption. The second 'dispersant' treatment will be applied to the intercooler and inlet manifold etc and this actually improves the metals ability to disperse heat and should lead to much cooler intake temps. The coolant pipes will also get coated, the hot pipe from the engine to the radiator with a 'thermal barrier' and the cold pipe from the radiator to the engine with the 'dispersant'

While the chassis was being painted, it gave us a chance to prep the motor and transmission for final fitment. For me no engine compares to rotary when at this stage. The contrasting colours of irons and rotor housings is just so cool!! We were working pretty hard as you can see from all the abandoned spanners ! LOL!

Here we are at paint. Every process of this build is done in house so this is in my make shift spray booth in the corner of the shop. That is Dan in the back round who does all the painting here, his MCNSPORT AE86 was actually featured as a random snap on here The underneath of the car resembles swiss cheese from all the drilling of spot welds holding brackets that we deemed unnecessary.

With the underneath painted its was time to flip it over and paint inside and under the bonnet. Feels great to get to this stage and get all the fab work done and now when something gets bolted on it can actually be tightened and wont be coming off again, hopefully for a long time.

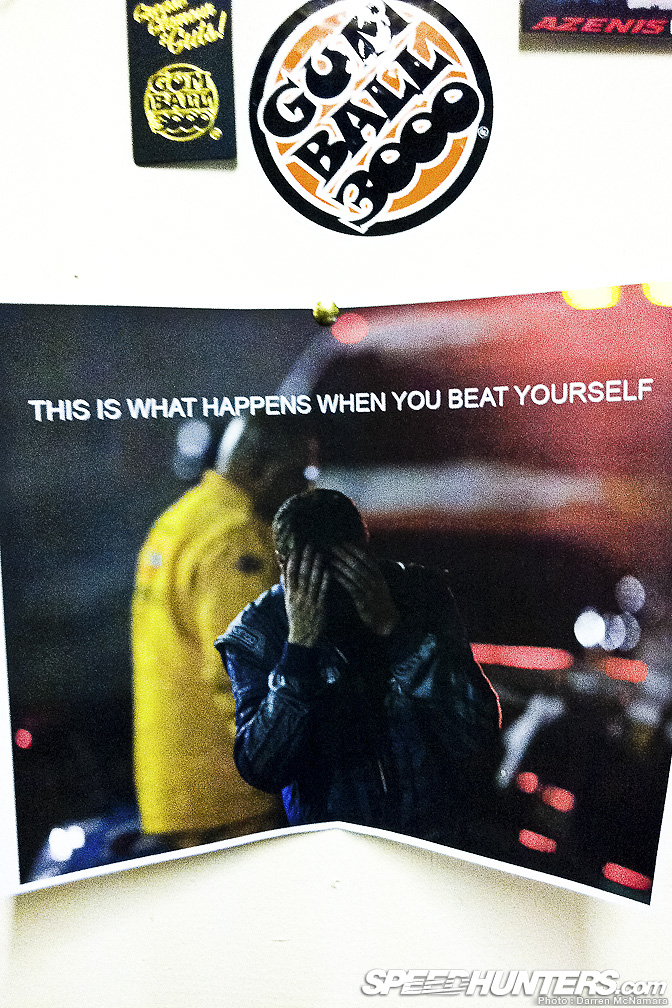

We received a box in the mail from ASD in North Carolina with our custom e-brake lever and they kindly included a nice picture for our office wall. Thanks guys!

New ASD e-brake and much more to come in the next update very shortly!!!

Stay tuned …

-

D-mac

Rad. I can't wait to see this car!

NICE TIG WELDS !!! KEEP GOING THAT AMAZING PROJECT!~

Loving it! Excited for the next installment!

that last pic is to funny

Moooaaar!

Also, whats the story behind the last pic?

Seeing this just makes me happy.

Love the pic ASD sent of what not to do again.

Car is going to be mental.

More build threads "it's like crack for speedhunters".

Master piece... spectacolare...bravo bravo!!

if you ever get another 13b manifold made check out DCW he makes some crazy stuff

I can't wait to see vids brap brap brap brap brap

Looks good - I'd lose that LIM for peripheral port goodness though.

Nice manifold, but exhausting the wastegate gases 'backwards' like that is a big No-No, isn't it...

the pics link are not showing up for me on this particular thread, please fix

Can you try clearing your cache and reload the page, I've checked it on a couple of different browsers and OSs and they images are loading fine. - Paddy

Is there anyone that the average joe could get his parts coated with "Thermal Barrier"?

Thanks for the comments guys

Story behind the pic is im always told i always beat myself and no one has actually beat me in twin battles

P-port would be overkill for turbo application

Daaaamn, ASD breaking your balls!

@ J

Last run of 3rd-place battle at Irwindale 2010, D-mac overrotated a little and went nose-first into a concrete barrier, taking himself out of the podium and almost totalling the car. He seemed pissed at losing to Tanner in the semis and took himself out against Takatori for 3rd.

is the engine a quad rotor r26b?!?!

why did you leave all the holes in the underneath?? wont it cause the interior to fill with smoke?? itl take alot to pressurise it enough

Ever heard of a spot weld drill bit? No excuse for jus drilling straight through the body like that. Just more amature Fab work on this build... and YES that wastegate dump pipe IS pointing the wrong way... Hopeless

@Mazdaspeed619sd: Contact Markus at Martelius Exhausts in Finland an he will hook you up

@andrew: No its a 13b 2 rotor

@matt: If you look closely you can see the centre hoop of the cage has brackets on it and the cockpit will actually be seperated from the rear seat area. Also the roof and side windows have air intakes for the rear mounted radiator which sould take out any smoke

@SKDKNG: I have heard of spot weld drill bits and i would agree with you if we were running a bodyshop but for a car like this it doesnt make a difference cos the floor is not structural anymore. I think you'll find the majority of wastegate pipe are done this way and i trust the people who made the exhaust as they make exhausts for wrc cars etc

there is also several other projects at mcnsport at the moment, Mike Fitzes SR20 FC RX-7, Chris Bradys SR20 AE86 and Damein Mulveys 1jz s13 , holy fook cant wait!!!

Lmao , uv cut the entire front off the car and SKDKNG is worried about a few drill holes

When engineering a turbo manifold you want to optimize flow to the turbo, the waste gate simply relives pressure and so doesn't have to optimize anything as it can (and always should be) be bigger than it needs to be.

Chill out SKDKNG, if you want the cool kids to like you, post a link to whatever perfect builds your involved in, or just take it easy.