I can’t quite explain it, but I’ve always been fascinated with turbocharged engines. I have always found the idea or harnessing exhaust gasses to help force-feed the intake side of the engine such an ingenious solution. While we are currently living through a massive comeback of the turbocharger as more and more modern engines, big and small, make use of this type of forced induction, I can’t help but have admiration for the pioneers of these systems. The eighties were when the turbo really caught on, and while road-going applications were often plagued with massive lag and less than optimal power bands, it was the motorsports side of things that were the most exciting. We all look back to the turbocharged era of F1 as one of the most memorable, where drivers had to fight with featherweight cars boasting power levels up to and beyond 1000 HP. These were F1’s golden years, where innovation and experimentation was being pushed continuously, be it with those wild 1.5L V6 turbocharged engines as well as the use of composites. But as interesting as this period in F1’s history was, it’s actually the experimental side of rallying that I want to touch on, and in particular the amazing work that the FIAT group was doing through their racing departments at Abarth and Lancia. While Group B (1982~1986) cars like the Lancia Delta S4, Audi Quattro S1 E2 and Peugeot 205 T16 defined the pinnacle of turbo application in rally, it was what was to come after this that was quite interesting. Group S was the proposed replacement of Group B, a class that would have limited power to 300 HP and forced manufacturers and race teams to experiment in new technologies, without relying on extreme power outputs and high speeds. However following the death of Henri Toivonen and his co-pilot Sergio Cresto in the ’86 Corsica rally the FIA banned Group B, and with it its replacement, Group S. From then on it would be Group A that would take over, where rally cars had to be based on true production cars, a class that wasn’t varied until 1997 when WRC rules came into effect, a sort of reintroduction of what Group S was supposed to do from 1987. However, before Group S was cancelled by the FIA, some manufacturers like Lancia managed to do a lot of development on what was to be a worthy replacement for the Delta S4.

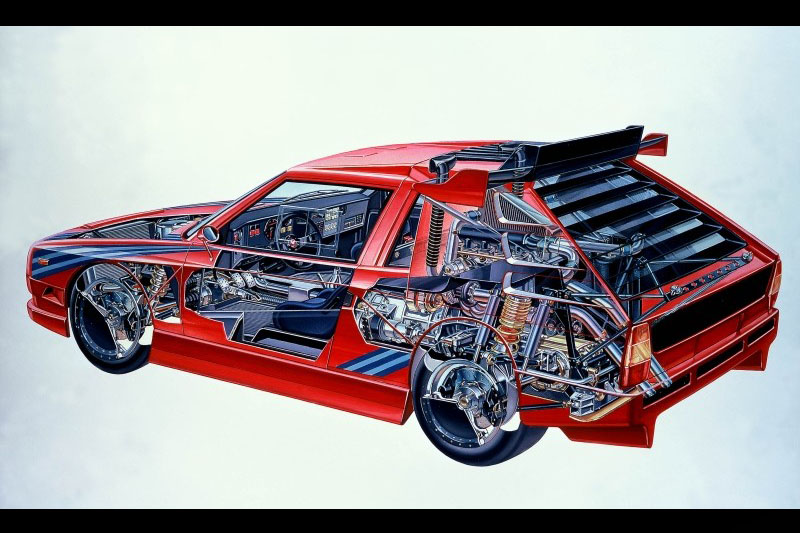

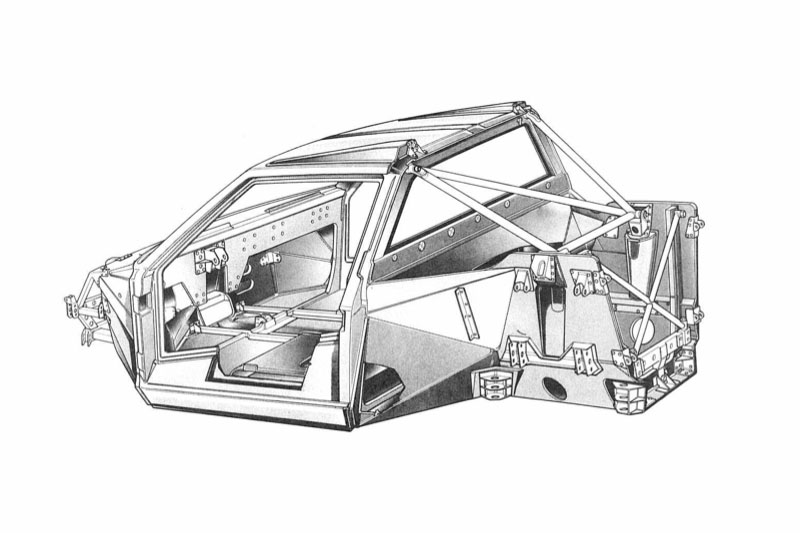

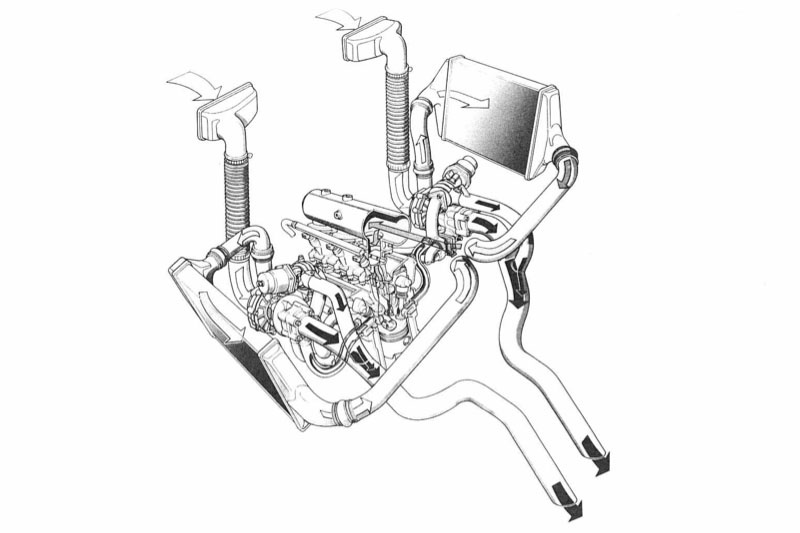

The Experimental Composite Vehicle, or ECV1, was what they came up with, a completely new car with the semblance of a Delta but boasting carbon fiber and Kevlar construction and a curb weight of 930 or so kilograms. Even the wheels were carbon fiber (6kg for an 8Jx16″ rim)! Mounted back under that awkwardly styled rear cowl was Lancia’s prototype “Triflux” engine, the motor I want to look at in this post. As you can see from the opening image this was unlike anything that had been created until then, and since.

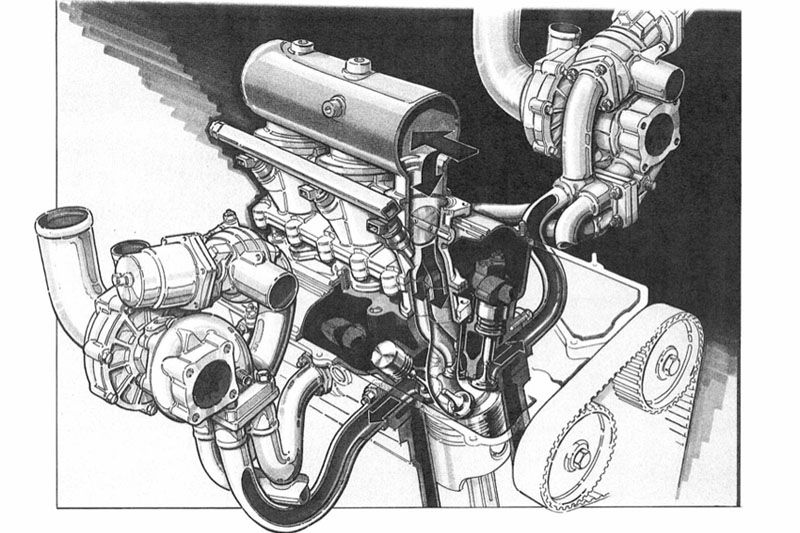

This 4-cylinder engine boasted a capacity of 1,759 cc, two turbochargers, a “Triflux” intake & head and the potential to develop up to 600 HP…

…from its mid-mounted position in the carbon fiber chassis, where it powered all four wheels through a rear mounted 5-speed gearbox.

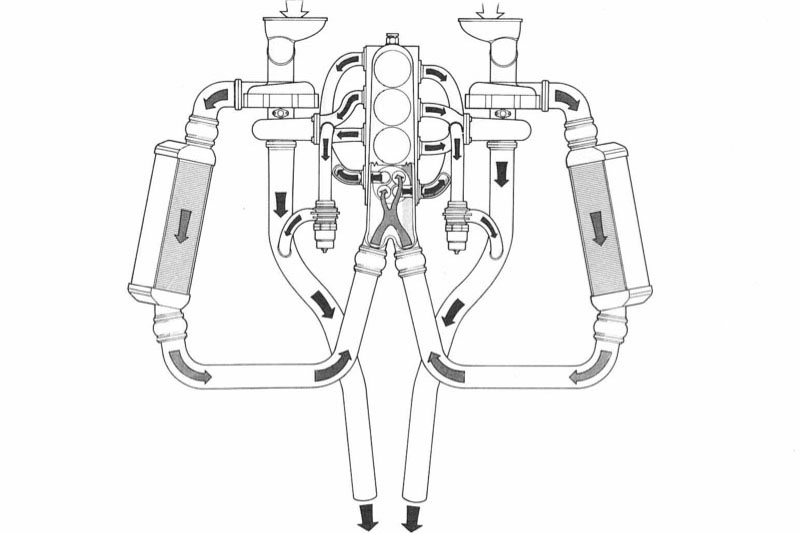

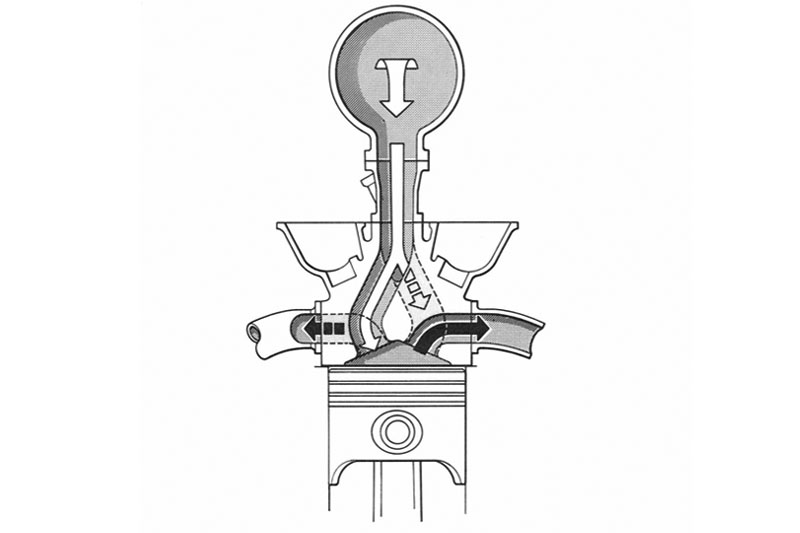

Claudio Lombardi was the engineer that came up with the Triflux head/intake design, the same man who had worked on the S4s twin-charged motor and later moved to Ferrari to head the F1 engine development there. The idea behind this motor was to come up with a small capacity and compact engine design that would not only yield a high power output but also allow for a linear power delivery thanks to the use of two turbochargers. The problem however was how on earth would you be able to feed and utilize two separate turbos from a 4-cylinder layout. Lombardi came up with the brilliant idea of feeding the four valves of each cylinder in an alternating pattern. So instead of having a conventional “hot” and “cold” side to the head where two pairs of valves are fed the intake charge and the other two dump exhaust gasses, the valves are fed according to a crossed layout or FID (Flusso Incorciato Doppio or Double corssed flow) as FIAT called it and patented it. This meant that the two top-fed valves (imagine an “X” pattern) would allow the compressed charge into the combustion chamber, and the other two would dump exhaust gasses out each side of the head.

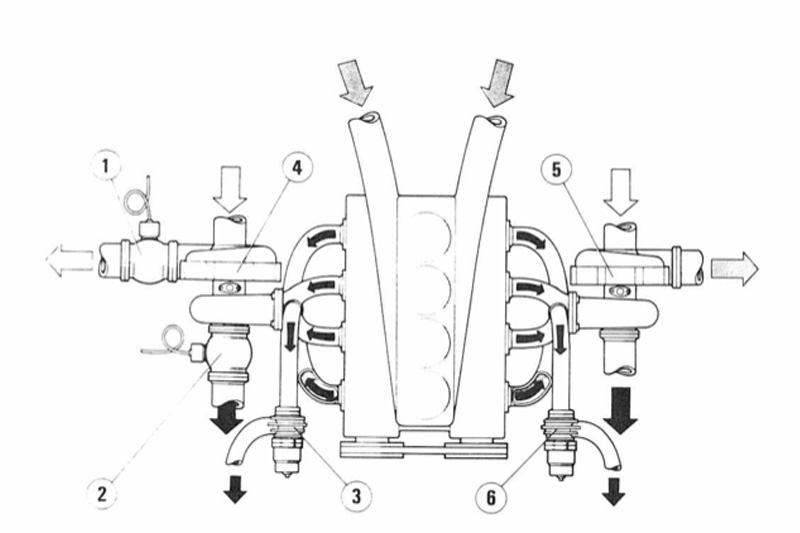

This is where the “Triflux” name comes from, as there are three distinct paths of flow, one for the intake and two for the exhausts. You can see this on the diagram above. Aside from the top-feeding inlet plenum, (which splits at the bottom around the spark plug to feed the two diagonally-opposed valves) and two separate exhaust manifolds, the Triflux also called for special camshafts that would be able to actuate 1x intake valve and 1x exhaust valve for each cylinder. On top of allowing the use of a twin-turbo set-up this solution had other evident advantages when applied to competition/motorsports. First of all by eliminating the conventional “hot” and “cold” sides to the head, there would be a far more uniform distribution of heat over the head itself. The more homogeneous heat dissipation means less chance of the head buckling under high loads as well as being far easier too cool through the liquid cooling system.

The layout of the manifolds, turbochargers, piping, intercoolers and again the piping feeding the intake plenum are also completely symmetrical.

They also planned that once variable vane geometry turbochargers would be ready for use it would be possible to remove wastegates altogether , to further simplify it all.

The Lancia engineers also came up with an application where a sequential turbo charger set-up could be used. Here, as you can see above, two electronically controlled valves (1 & 2) can be added to the larger turbo limiting either or both the outputs of the compressor and turbine sides to allow a smaller turbo (5) to be ran at full capacity on the opposite exhaust side. When this one runs out of puff the valves can be open and the lager one (4) can take over. 3 & 6 on the above diagram point to the external wastegates. Lancia learned a lot on the S4 with the car’s twin charger set up which utilized both a supercharger as a turbocharger to guarantee explosive acceleration at any rpm.

This image of the Triflux engine in the back of the ECV1 is from the Walkers Garage website, the guys that supplied the intercoolers and radiators to the recently rebuilt ECV1 prototype.

http://www.youtube.com/watch?v=E47Hk5ObWYQ

The car was shown at the 2010 Rally Legend event in Italy where rally legend Miki Biasion got the chance to put it through its paces. The EVC1 was put together and restored from the parts that were left after its development 25 years prior by its current owner and another rally legend, Giuseppe “Beppe” Volta, famed for building the Volta Fiat 124, Fiat 131, Lancia Stratos, Lancia 037 and the Lancia Delta S4.

Volta is quite handy behind the wheel himself as you can see above, where he plays around with the 600 HP ECV1 during a photoshoot.

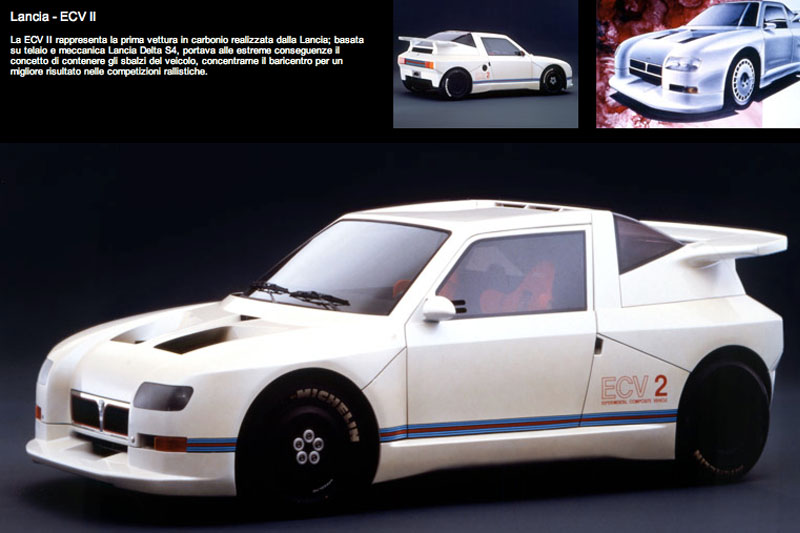

Despite Group S being cancelled, Lancia decided to go ahead and improve on the EVC 1 and built the ECV2 which was in all effects a rebodied ECV1. The same carbon fiber and Kevlar chassis was used as was the Triflux engine, albeit with some more compact ancillaries as the rear of the car was quite a lot more compact. The body was designed by Carlo Gaino of Synthesis Design. It’s hard not to wonder what would have happened if the Triflux engine would have been allowed to prove itself in motorsports. Despite this it still stands out as an ingenious solution and hopefully one that – as turbocharging continues to grow in the pursuit of better performing and more economical engines – we might see come back in the future.

Lancia Triflux engine specs:

Power: 600 HP @ 8,000 rpm

Torque: 540 Nm (398 lb/ft) @ 5,000 rpm

Layout: In-line 4

Bore x stroke: 88.5 mm x 71.5 mm

Capacity: 1,759 cc

Compression ratio: 7.5:1

Head: “Triflux” with “FID” double-crossed-flow

Force Induction: 2x KKK K26 with twin intercoolers

Ignition: Weber Magneti Marelli IAW electronic fuel injection, electronic boost control

Lubrification: Dry-sump

Many thanks to Lancia for supplying the original research documents for the Triflux engine and Delta ECV1.

-Dino Dalle Carbonare

It is wonderful that somebody still remembers the pioneer work of the italian engineers. They are not only famous for Pasta and Pizza, and there's far more than just Ferrari and Lamborghini. Grazie Dino for this wonderful post! I hope to see in future more Italian manufacturers,that bring out performance cars at a resonable price tag, with an attractive engine and power layout, and who can compete with the todays JDM, Euro and US sports cars.

Wow. Some serious stuff here, not just "ooooh, look at that olde wheels". More of that.

Campione di tutto WRC ! Sei grandisimo Dino

Great article. Only one mistake: The gearbox wasn't rear mounted but centrally, between the drivers. Sorry, I'm anal about rally cars

@Vittorio Jano The FIAT documents state the gearbox was mounted in "longitudinal rear position." I think by this they meant it was attached to the mid-mounted engine hence "rear" mounted. So yes it was "in" the transmission tunnel, sending 30% of the drive via a carbon propshaft to the front diff

This is actually a really cool post Dino, bravo!

This is actually a really cool post Dino, bravo!

This is actually a really cool post Dino, bravo!

The engine is very similar in concept to the 1966 BMW Formula 2 engine designed by Ludwig Apfelbeck.

The engine is very similar in concept to the 1966 BMW Formula 2 engine designed by Ludwig Apfelbeck.

The engine is very similar in concept to the 1966 BMW Formula 2 engine designed by Ludwig Apfelbeck.

how was crankshaft and camshafts syncronysed? there is no single belt linking cam and crankshaft...

how was crankshaft and camshafts syncronysed? there is no single belt linking cam and crankshaft...

how was crankshaft and camshafts syncronysed? there is no single belt linking cam and crankshaft...

Awesome. You guys (speedhunters) have been doing some really killer articles lately. This is going to be a good year.

Awesome. You guys (speedhunters) have been doing some really killer articles lately. This is going to be a good year.

Awesome. You guys (speedhunters) have been doing some really killer articles lately. This is going to be a good year.

That's an exceedingly and needlessly complicated solution to a simple problem. Nevertheless, I can appreciate the engineering that went in to this marvel.

That's an exceedingly and needlessly complicated solution to a simple problem. Nevertheless, I can appreciate the engineering that went in to this marvel.

That's an exceedingly and needlessly complicated solution to a simple problem. Nevertheless, I can appreciate the engineering that went in to this marvel.

I hate every season that a Lancia misses in the WRC.

I hate every season that a Lancia misses in the WRC.

I hate every season that a Lancia misses in the WRC.

Brilliant. Yet more educational posts from Speedhunters. More please!

Brilliant. Yet more educational posts from Speedhunters. More please!

Brilliant. Yet more educational posts from Speedhunters. More please!

Oh, that's not sarcasm, by the way. Sorry if it could be taken that way. I'm tired.

Oh, that's not sarcasm, by the way. Sorry if it could be taken that way. I'm tired.

Oh, that's not sarcasm, by the way. Sorry if it could be taken that way. I'm tired.

@ArtemShemetenko What do you mean there isn't Looka t the first pic, there is. There's prolly a gear pair inside the casing, that transfers the output shaft a bit higher. It'd be interesting to know why that was done, there has to be a reason.

@ArtemShemetenko What do you mean there isn't Looka t the first pic, there is. There's prolly a gear pair inside the casing, that transfers the output shaft a bit higher. It'd be interesting to know why that was done, there has to be a reason.

@ArtemShemetenko What do you mean there isn't Looka t the first pic, there is. There's prolly a gear pair inside the casing, that transfers the output shaft a bit higher. It'd be interesting to know why that was done, there has to be a reason.

This in the 80's, and yet the Americans still swear by OHV engines??

This in the 80's, and yet the Americans still swear by OHV engines??

This in the 80's, and yet the Americans still swear by OHV engines??

i heard Inno di Mameli while i read this. l'italia s'è desta

i heard Inno di Mameli while i read this. l'italia s'è desta

i heard Inno di Mameli while i read this. l'italia s'è desta

hahahah @ 2:44 in the video.. I don't speak Italian but I'm pretty sure I know what that dude exclaimed!

hahahah @ 2:44 in the video.. I don't speak Italian but I'm pretty sure I know what that dude exclaimed!

hahahah @ 2:44 in the video.. I don't speak Italian but I'm pretty sure I know what that dude exclaimed!

@TomHoward Because the American ideology for engine building is to make them as simple and reliable as possible. Turbos and high rpms are great, but it comes at the cost of added complexity and less reliability. As of now the standard performance OHV engine has no problem keeping up with the more complicated OHC engines and in many cases surpasses them(don't forget that some of the fastest times at places like the Nurburgring are held by OHV engines). Most of this can be seen just by observing the immense popularity of LS swaps in drift cars nowadays and the reasoning behind it. I don't know if you know the saying "if it isn't broken, don't fix it", but until the OHV engines can no longer compete against the more complicated engines there's really no reason to change it.

@TomHoward Because the American ideology for engine building is to make them as simple and reliable as possible. Turbos and high rpms are great, but it comes at the cost of added complexity and less reliability. As of now the standard performance OHV engine has no problem keeping up with the more complicated OHC engines and in many cases surpasses them(don't forget that some of the fastest times at places like the Nurburgring are held by OHV engines). Most of this can be seen just by observing the immense popularity of LS swaps in drift cars nowadays and the reasoning behind it. I don't know if you know the saying "if it isn't broken, don't fix it", but until the OHV engines can no longer compete against the more complicated engines there's really no reason to change it.

@ArtemShemetenko I think the camshafts are gear-driven by the crankshaft. We can't see those gears because they're very probably inside the carter, to protect them. Then, the ancillaries are belt-driven from the camshaft and from that intermediary shaft..I think they chose external belts for ease of replacing.

Well, that's my take, I may well be wrong!

A great article! I never thought I would join the same discussion as Vittorio Jano:-) The Triflux engine is truly remarkable. After the S4 engine I think it was a shame to see Volkswagen beat Italy by mass producing their turbo/supercharger GT engine. I own an Integrale myself, but to me Lancia is dead. Really sad, but the way they manage the brand it would be better to kill it off completely. Thanks Dino!

@Hanma @TomHoward one might argue that if people had been focusing entirely on OHC engines during the past two decades rather than doggedly ignoring them in favour of "reliability," they would in fact be at the level of reliability that you expect

when you play rts games you don't spam resources on an inferior unit and then tell people that the superior unit sees less use (and also imply that the inferior unit is actually better) because it's less effective, when in reality it is only less effective because you have given it very little time and attention. we'd probably have IRS mustangs now if ford had followed through on that concept in the '60s, and no, a cobra with a rear suspension designed and built by a third party does not count

Thanks for posting up all the old tech... Nice to see this again. It's a shame Group B was killed off

The only drawback is mixing intake and exhaust valves on the camshafts.

With the hot and cold side engine, intake valves on one cam and exhaust on the other, overlap can be adjusted and fine tuned with the sprockets.

With the diagonal flow and hot and cold valves mixed on the shafts, it's just as stifling as tuning a SOHC. The camshaft has to be changed to adjust the valve overlap.

When solenoid operated valves come on the market, this layout will really shine.

Great article! No doubt one of the coolest cars I've ever heard of.

Very nice article! I would appreciate more articles about engines and stuff.Keep up the good work!By the way, a wallpaper of the first picture would be great!

Greetings from germany

I agree with the articles, and stick to the lesser known underground stuff, like this, some other less known machinery, mainly from the 80s, JDMs tuff, etc. And not just engines, technical stuff in general is really cool.

As for the picture, i doubt a wallpaper sized pic is possible, since i think it's a very old photo and comes in this resolution and not much else. At least it's not that useable for modern monitors with high resolutions...

Maybe for some racing applications, but not much more. For on road applications this is actually quite a horrible layout - you have the intake manifold on the top, which demands raising the bonnet (not possible, since manufacturers are trying to lower them, not always successfully), you'd have spark plugs under the manifold (you'd need to remove it to change them), you need bigger bores to fit in 4 valves, a spark plug AND an injector with modern engine tech - this sin't such a problem by itself, since it has been done, but you need to take into account the manifold, which is still over the whole head. And it only works for a twin turbo setup.

I doubt it'd get much use today, maybe in some racing applications, but that's more or less it. With onroad engines you also have the problem of different engine types, where you use the same block for twin turbo and single turbo variants, you'd have some problems with 2 hot sides (if you want to shoehorn a triflux in a car, designed only for inline engines), etc.

I sound like a pessimist, i know. THese are only the problems i see with todays use. On the other hand i applaud Lancia's engineers for coming up with something like this and i'd actually love to see a modern incarnation of it. It's just that i'm a pesimist when it comes to making something new in this crazy world, where only profits matter. Sadly. :/

This article is one of so many reasons why Speedhunters is set as my homepage

@jonas maurstad Didn't you know that we engineers have internet in the heaven too

@ComJive @Hanma Mercedes Benz M156 engine with DOHC: .6.2 Litre, 563BHP in the base model SLS, up to 622BHP in the Black Series SLS

2013 GM LT1 Small Block: 6.2 Litre 450BHP with OHV

Both 6.2, both N/A

Fantastic article. I came across a writeup on this engine and ECV1 in one of my old 80's Car and Driver mags, and was intrigued. Great to read more about it and the pics and cutaways are great, makes a lot more sense now. Great work.

@TomHoward They actually do have their advantages. Wiki it up, a 4.6 Modular V( from FOrd has bigger outside dimension than the older 5.0 unit. OHC vs. OHV. There's a simmilar story with GM's OHC vs. LS (OHV) engine (4.something is bigger than a 5.7 LS). OHV gives a much lower height and width due to smaller heads. Though i don't know what happens when you want to cram 4 valves into each cylinder, does OHV work with that?

ComJive the only companies that didn't develop OHC engines are from the US. The European and Japanese comanies almost without exception developed OHC engines. With some nifty improvements as well (variable valve timing, FIAT's MultiAir, etc.).

its amazing how these engineers can create such beuty in their ingines and designs but then make the ugliest body to put it in. obviously having a pretty looking car wasnt on the top of their list but .. jeez guys, did you want it to look like bad?

@TomHoward @ComJive @Hanma Oh yeah, lets compare a motor that costs well over 15k and is hand-built, with a LT1, which one can find for under 3k easily, and is mass produced. Based on your logic lets take a typical sprint car motor, all motor and over 800 hp using OHV, yeah its over $25k but who cares because the origonal comparison is one of the dumbest things I have ever witnessed. Comparing a motor that is used in tahoes with a $200k supercar motor

@CarpeDeez @TomHoward @ComJive @Hanma

What does money have to do with it? Whether the engine costs £2k or £100k to build, that doesn't change that OHV is outdated.

As fred-4 already stated, BMW had the Apfelbeck radial diametral layout of the valves on their F2 cars in the early 70s, so it's not the great new concept FIAT claimed back then.

The rest however is absolutely mental and breathtaking, thank you, i like the engine and technical articles a lot.

Maybe there's place for a feature of said Apfelbeck-Engine

http://touringmm.blogspot.de/2011/07/apfelbeck-zylinderkopf.html

How is it outdated? Are stairs "outdated' because someone invented the escalator? It's a mechanical device. It has fewer moving parts and phenomenal power density and is perfectly suited to the application it's intended for. A mass produced, entry level sportscar. I don't understand why you're offended?

www.araoengineering.com

yessss that noise!!!!! So did anybody get lost or dizzy following the airpath in the pictures?

perpetualroad.wordpress.com

http://beautifullyengineered.tumblr.com/post/9630641665/the-lancia-triflux-engine-is-beautifully

@ComJive @TomHoward That's an interesting argument, but rts games are all pulling resources from the same source whereas auto manufacturers are all separate entities. You could say each one is a different player each playing their own game. You're also forgetting the fact that one costs much much more than the other to develop, produce, and maintain. It would actually make sense to continuously improve the old technology for a fraction of the price of developing a new unit, especially if the old tech could easily keep up with the new stuff. That would be the the defense for keeping OHV technology until it can no longer compete as far as economics go anyways.

Each company has their own approach and ideology behind their designs, and I personally think that individuality should be encouraged rather than looked down upon by "auto elitists".

P.S.

Random side note, but I happen to have one of those IRS Cobras with an aluminum DOHC engine lol. I personally don't mind the new live axle Mustangs though. It keeps the costs low and they can still out perform nearly everything in their price range.

@TomHoward @CarpeDeez @TomHoward @ComJive @Hanma Damn, you really have to make a stretch trying to compare an LT1 to an AMG engine haha.

AMG is probably wiping their tears with 100 dollar bills in frustration of not being able to build a faster car than the Viper or Vette.

Also fun fact for the day, I'm pretty sure that OHV tech was invented AFTER OHC.

@Gianluca FairladyZ Grazie Gianluca!

@Nico Leone Grazie Nico!

@Fred-4 Wasn't that NA?

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@majik16106 Thanks, I'd like to do more of these, but they do take some time to put together

@speargunsANDracecars But how cool is it!

@speargunsANDracecars But how cool is it!

@speargunsANDracecars But how cool is it!

@speargunsANDracecars But how cool is it!

@speargunsANDracecars But how cool is it!

@speargunsANDracecars But how cool is it!

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@Autolegend Same here! It gives me shivers to see how FIAT have destroyed Lancia

@P1 Race Photography lol

@P1 Race Photography lol

@P1 Race Photography lol

@P1 Race Photography lol

@P1 Race Photography lol

@P1 Race Photography lol

@ComJive haha

@ComJive haha

@ComJive haha

@ComJive haha

@ComJive haha

@ComJive haha

@zephoto Yeah I was hoping nobody would notice that

@zephoto Yeah I was hoping nobody would notice that

@zephoto Yeah I was hoping nobody would notice that

@zephoto Yeah I was hoping nobody would notice that

@zephoto Yeah I was hoping nobody would notice that

@zephoto Yeah I was hoping nobody would notice that

@roninlotus211 Sure is!

@roninlotus211 Sure is!

@roninlotus211 Sure is!

@roninlotus211 Sure is!

@roninlotus211 Sure is!

@roninlotus211 Sure is!

@primoz Yeah as primoz said that is as big as they came

@primoz Yeah as primoz said that is as big as they came

@primoz Yeah as primoz said that is as big as they came

@primoz Yeah as primoz said that is as big as they came

@primoz Yeah as primoz said that is as big as they came

@primoz Yeah as primoz said that is as big as they came

Thanks man!

Thanks man!

Thanks man!

Thanks man!

Thanks man!

Thanks man!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@Phishy Yeah again have to thank Lancia on this! Awesome guys!

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

@zamm333 1) it was the 80s 2) it's function over form, or function-dictated form lol

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

Similar but different, the valve actuation, intake positioning (IN & EX on same side) but the differences were because it was NA. I think it was actually designed for a single cyl. bike engine initially

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

@Hanma @TomHoward i wouldn't go so far as to say they're playing different games. it's the same game (the basic ideas of OHV vs OHC are available to anybody willing to use them in a design), but different strategies and different campaigns maybe. my strategy has always been biased towards researching advanced stuff and not doing much until i could work with them so maybe i'm biased too

those cobras are awesome btw, probably the only mustangs from that body generation that i still see without horrible exterior mods and chromed taillamps. i just lose a lot of time imagining a world in which ford had gone through the costs of developing new IRS decades ago, and now had refined IRS as well as they have live axles

as a sort of side note, i do enjoy how we're discussing the "poor" reliability of modern OHC engines as if we're still living in 1970s britain. having a really unreliable car is pretty rare these days, and OHC layouts are not usually the culprits in those situations anyway, so the whole argument of IT'S MORE SIMPLE AND BETTER AND DOESN'T BREAK loses one of its points in real practice. we're not talking about 1960s alfa spiders here, we're talking about a layout which HAS had a huge amount of resources devoted to it. they've negated the added "complexity" and the benefits (better engine breathing, better port configurations) outweigh the benefit of having a simpler valve system these days. the real problem is that these automakersso on don't want to spend money developing an OHC which would be relatively worse than extant OHCs in terms of the qualities you mentioned, because they spent so much time with OHVs instead, so they just keep digging the OHV hole instead

at the end of the day it doesn't really matter that much as long as they try to find ways to make OHVs better, like the way ford works tirelessly to compensate for the mustang's live axle, to the point where it might not be a disadvantage

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Is is just me or does that 8th picture conjure up nostalgia for the good old days when things such as this were drawn by hand, with ink, on paper? I realize that computer generated models of this subject matter are superior in both the time necessary to create them, and the ability to tweak them afterward, but the result is nowhere as visually appealing and robust as a marker rendering such as this. I really have a profound admiration for the skill and patience of the artist who drew it.

And yes, quite a remarkable power plant for sure, racing technology was no doubt impressive back in the 80's, which has recently been gaining more and more appreciation from me due to all these 80's-themed posts. Thanks for reminding us of how great this decade of motorsport was SpeedHunters crew! I'm proud to have been born in the same decade as all of these awesome machines (1983).

Nice article! More like this please, technical articles are always welcome.

Nice article! More like this please, technical articles are always welcome.

Nice article! More like this please, technical articles are always welcome.

Nice article! More like this please, technical articles are always welcome.

Nice article! More like this please, technical articles are always welcome.

Nice article! More like this please, technical articles are always welcome.

@Mighty_Mite50 Noted:)

@Mighty_Mite50 Noted:)

@Mighty_Mite50 Noted:)

@Mighty_Mite50 Noted:)

@Mighty_Mite50 Noted:)

@Mighty_Mite50 Noted:)

@VelociTT I agree, it's like comparing digital pictures to film

@VelociTT I agree, it's like comparing digital pictures to film

@VelociTT I agree, it's like comparing digital pictures to film

@VelociTT I agree, it's like comparing digital pictures to film

@VelociTT I agree, it's like comparing digital pictures to film

@VelociTT I agree, it's like comparing digital pictures to film

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

When I saw the article's name I was mumbling like a madman "Yes yes yes, let it be THE Triflux!!!" and when I saw the first picture...I almost moan. This engine is automotive porno!!!Great articles, very educational. Keep 'em coming, it would be amazing if you made a series of articles about the all-time most recognized engines like the RB26DETT and the 2JZGTE.

@ComJive @TomHoward With the way patents work and the competitive nature of companies, I think it's safe to say they are not working together to advance technology. That's not to say the American companies aren't doing their part in developing new platforms. Ford's new ecoboost engines seem to have a lot going for them.

As far as reliability goes, your totally right. It's the modern age and OHC engines are just as reliable as OHV engines. Turbos are steadily becoming more reliable as well. That doesn't change the fact that it's adding complexity, weight, and cost to the equation though. (paying for 4 cams instead of 1 or 2 is a bitch). The point I was really trying to make originally is that OHV engines are proven cost effective platforms that are tuner friendly while still being extremely competitive. Saying that the technology is outdated and should be dropped is just an ignorant thing to say. Different companies have different styles and approaches to building cars and I think that diversity should be encouraged. As long as the technology still competes on level ground as the newer stuff, there's no reason to scrap it quite yet. I'd personally like to see the absolute limits of an OHV engine or a live axle, but so far it doesn't seem like we've gotten even close.

@ComJive @TomHoward With the way patents work and the competitive nature of companies, I think it's safe to say they are not working together to advance technology. That's not to say the American companies aren't doing their part in developing new platforms. Ford's new ecoboost engines seem to have a lot going for them.

As far as reliability goes, your totally right. It's the modern age and OHC engines are just as reliable as OHV engines. Turbos are steadily becoming more reliable as well. That doesn't change the fact that it's adding complexity, weight, and cost to the equation though. (paying for 4 cams instead of 1 or 2 is a bitch). The point I was really trying to make originally is that OHV engines are proven cost effective platforms that are tuner friendly while still being extremely competitive. Saying that the technology is outdated and should be dropped is just an ignorant thing to say. Different companies have different styles and approaches to building cars and I think that diversity should be encouraged. As long as the technology still competes on level ground as the newer stuff, there's no reason to scrap it quite yet. I'd personally like to see the absolute limits of an OHV engine or a live axle, but so far it doesn't seem like we've gotten even close.

dont underestimate your audience as folks who just like to look at pics of sweet cars, the mechanical bits and engineering like this is the reason so many readers here are in love with cars to begin with. keep the technical realed stuff coming, great post

dont underestimate your audience as folks who just like to look at pics of sweet cars, the mechanical bits and engineering like this is the reason so many readers here are in love with cars to begin with. keep the technical realed stuff coming, great post

oh thank god something different and technical on Speedhunters. good job guys!

oh thank god something different and technical on Speedhunters. good job guys!

@AlejandroRamirez That's a very good idea! So much to show...

@AlejandroRamirez That's a very good idea! So much to show...

Oh I never have graham!

Oh I never have graham!

@KBR Thank you KBR!

@KBR Thank you KBR!

Not *quite* completely symmetric. The turbos are the same on each side (not mirror imaged), so the piping layout has to be a little different on the left and the right.

Not *quite* completely symmetric. The turbos are the same on each side (not mirror imaged), so the piping layout has to be a little different on the left and the right.

I wanna see a look at the Delta S4 motor! Turbo charged with a supercharger on a clutch for low end power? come on! More articles like this!

I wanna see a look at the Delta S4 motor! Turbo charged with a supercharger on a clutch for low end power? come on! More articles like this!

@KH15 Sounds like we should visit the Volta rally shop and do a proper featured shoot on all his cars!

@KH15 Sounds like we should visit the Volta rally shop and do a proper featured shoot on all his cars!

@asad137 I think they may have been referring to the length of the piping, obviously the turbos are identical so when placed on opposite sides of the engine the compressor outlet would be opposite

@asad137 I think they may have been referring to the length of the piping, obviously the turbos are identical so when placed on opposite sides of the engine the compressor outlet would be opposite

I read this in a Need for Speed SE narration voice. e.g. http://www.youtube.com/watch?v=V8-8SyimDDo

@milkplus Fewer moving parts? How does having a camshaft, pushrods, rockers AND valves come out to fewer moving parts than camshafts and valves? Okay, we're then compating 4 camshafts against one and 32 valves vs. 16 in a V8 engine, but those are the details, that are neccessated by the design itself - the whole point of an OHV is to have one camshaft and it's hard to have 4 valves per cylinder.

@speedhunters_dino Yes, but the valve arrangement with exhausts on both sides was what I was referring to. I did not know anyone else had ever attempted it.

awesome article,more of the same please

Very cool stuff. Thanks for posting!

haha you made me laugh

@TomHoward OHV engines are dimensionally small than OHC engines of similar displacement and the fact that the american car companies have been using the OHV engine for decades does make them cheaper to make. But that should not be the only reason to keep using the technology. GM made a DOHC engine in the 80's ZR1 vette. (I think that gen). from what i remember it was by far the best engine they had made in terms of reilablity and power per liter, but the cost was way high. The customers also didnt like the fact that they didnt have OHV in the vette. so they junked the engine. new tech always cost more at first.

Hanma, what is the bar set for complexity. the OHV engine has way more components just to actuate a valve. Lifter, push rod, and rocker arms al contribute to more complexity. while some OHC still use rocker arms, that is becoming less prevalent. All engines need to be more efficient just to make the MPG standards the government is setting and the OHC engine is more efficient.

@milkplus Freakin awesome, but WAAAAYY to much money

I also dig he technical vibes Mr D C. Let me see if i've understood: the primary advantage of the triflux valve sytem was that it permitted parallel twin turbochargers, which offers a weight saving (and complexity saving) over sequential twin turbochargers...?

@Hanma @TomHoward There is a law of engineering which states that the last iteration of an old technology is more efficient than the first iteration of a new technology. In order to break through this point and get the most out of the new tech, the designer/manufacturer needs to make an up-front (and at-risk) commitment of resources. This seems to be something US car manufacturers are more reluctant to do than their European and Asian competitors, and may be reflected in the current state of the US car industry and the quality of its output.

I would have thought that the reasons for the difference have as much to do with cost (the cost of fuel cost, the cost of cars) as anything else eg simplicity and the "if it ain't broke" philosophy. When cars and fuel are relatively cheap - as they still very much are in the USA - then marginal improvements in efficiency are of marginal value. Hence you get obsolete technologies lingering beyond their idealised lifespan.

Thk u you guys for this information. very nice

great post, this kind of stuff usually stays on my computer longer because I read through it pretty finely.

Best article ever!

@GeorgeKrapivko Thank you!

@BenjaminSaucier Good to hear!

@tenpennyjimmy Wouldn't say "complexity saving" but yeah, smaller capacity for more power and depending on layout the turbos can be packaged and fitted symmetrically in a variety of ways. Mind you with modern engines having individual coils x each spark plugs and direct injection, space would be problematic on such a layout. Oh and variable valve timing & lift would be difficult. Still it's very cool

There was a certain Luciano Tamburini who used to run in Autocross and the Pikes Peak with a Triflux engined buggy, so there should more than one Triflux head around. Don't know how many of them are replicas, though. Anyway, I want one!

There was a certain Luciano Tamburini who used to run in Autocross and the Pikes Peak with a Triflux engined buggy, so there should more than one Triflux head around. Don't know how many of them are replicas, though. Anyway, I want one!

@primoz I guess you have never worked on a 3000GT VR4. Exact same system (but a v6 not an inline 4). You have to remove the manifold you change out the rear 3 spark plugs.

@primoz I guess you have never worked on a 3000GT VR4. Exact same system (but a v6 not an inline 4). You have to remove the manifold you change out the rear 3 spark plugs.

@Vr4joe Indeed i haven't. Haven't worked on a car at all actually.

@Vr4joe Indeed i haven't. Haven't worked on a car at all actually.

@Andrea1234 Yes that's correct there are a few as I've seen some fitted to prototypes/hill climb cars on youtube

@Andrea1234 Yes that's correct there are a few as I've seen some fitted to prototypes/hill climb cars on youtube

OHCams still need some way to take up lash, typically with a follower and lash adjuster, the pushrod itself is the only additional part. There is less drag associated with 16 fewer valve springs, and less opportunity for a single component to fail. I have no dog in the fight, I've owned DOHC VVT cars before and have never suffered a top end failure (even on ones I've rebuilt).

I'm just suggesting that lower friction, brutal simplicity and power density are desireable attributes in an ICE.

OHCams still need some way to take up lash, typically with a follower and lash adjuster, the pushrod itself is the only additional part. There is less drag associated with 16 fewer valve springs, and less opportunity for a single component to fail. I have no dog in the fight, I've owned DOHC VVT cars before and have never suffered a top end failure (even on ones I've rebuilt).

I'm just suggesting that lower friction, brutal simplicity and power density are desireable attributes in an ICE.

Dude! This is the kind of text that I like to share it with friends, because it shows how amazing engineering is and how a person who enjoys it can write an amazing article!

Dude! This is the kind of text that I like to share it with friends, because it shows how amazing engineering is and how a person who enjoys it can write an amazing article!

@speedhunters_dino @tenpennyjimmy Coils doesnt need to stay ON the sparkplug, you can still have a tiny wire to it, have the coils on the plenum and wires down :)not much against using it now, apart from height of the engine...

@speedhunters_dino @tenpennyjimmy Coils doesnt need to stay ON the sparkplug, you can still have a tiny wire to it, have the coils on the plenum and wires down :)not much against using it now, apart from height of the engine...

@speedhunters_dino @AlejandroRamirez VVL, VTECH, VVTI etc, those techs, and so many more would be good

Analyzing here, with this arrangement in which there is no area "hot" and "cold" in the chamber, the displacement of the flame front becomes more uniform and thus further reduces the risk of knocking and hence the engine can work with higher boost pressure

@Rodrigo Coutinho Yes absolutely. I actually forgot to mention this, they found that even at high boost there was noticeably reduced levels of detonation. Thanks for reminding me!

@Rodrigo Coutinho Thanks man!

@TomHoward @ComJive @Hanma Thats a pretty retarded argument Tom and it shows a very simplistic understanding of engines. You're listing peak torque numbers and you're not going to list torque? Peak figures mean much less than the curve and shape of the horsepower which is by the way calculated based off of torque.

What is the BMEP of each engine? BMEP is a much more accurate way to compare two engines than to just say they are both 6.2 and one makes x and one makes y.

Educate yourself before you decide to flap that loose trap:

http://www.epi-eng.com/piston_engine_technology/comparison_of_cup_to_f1.htm

Until you understand and comprehend all of that you really have no business making a comment like the one you made originally.

@TomHoward@ComJive@Hanma

"Two of the most accepted performance-comparison yardsticks are Brake Mean Effective Pressure (BMEP, explained HERE) and Mean Piston Speed (MPS, explained HERE).

The BMEP of the Formula One engine at peak torque (table line 13) is 15.17 bar while the Cup engine produces a peak torque BMEP of 15.12 bar (0.3 % less).

At peak power, the Formula One BMEP value (table line 22) is 14.6 bar while the Cup figure is 14.0 bar (4.1% less).

It is evident that producing 15.17 bar BMEP at 17,000 RPM and 14.6 bar at 19,250 RPM are remarkable achievements, given that the ratio between Friction Mean Effective Pressure (FMEP) and BMEP is much higher at Formula One than it is at Cup RPM.

However, it is astonishing that the Cup BMEP (remember, flat-tappet cam, pushrod / rocker arm, two-valves-per-cylinder, single carburetor) is only 0.3% less than the Formula One figure at peak torque, and only 4.1 % less than Formula One at peak power.

Even more revealing, at peak power RPM (table line 19) the Formula One engine MPS (table line 23) is 25.5 m/s (5025 ft/min), while that of the Cup engine is less than 3% lower at 24.8 m/s (4875 ft/min). At redline, the Formula One MPS is 26.5 m/sec, while the Cup MPS is a stunning 27.5 m/sec.

To put those numbers in perspective, Professor Gordon Blair wrote (Race Engine Technology, issue 27) that 26.5 m/sec was the highest he had seen.

While being cautious with empiricisms, it is interesting to compare the nondimensional values of BMEP x MPS (bar x m/sec) at peak power (table line 24) and at peak torque (table line 15)."

@AlejandroRamirez i too vote for more engine tech! i LOVE this stuff!

oh the sound that comes from that beautiful thing.. droooll.prototype cars are always fun.more rs200? or the toyota 222d (mr2)?:3<3

@speedhunters_dino you might be right with the bike engines i think

The Lancia Delta S4 is my favorite car ever built. Period. The noise of the supercharger coming, followed by the BOV leaving is just amazing. I was only born in '91, but after playing the first DiRT and driving the S4, I fell in love with it. And after learning more about it, Henri became my favorite driver, despite his crash 5 years before I was even born. Ive seen tons of amazing cars in my life so far, but the one I want to see over everything else is the S4. Just once would would make me happy. And maybe a ride!

@EricSeanDelaney

I live in switzerland mate, here we have hillclimb championship with two S4 in the entry list! you can trust me, the sound is freakin awesome!

@EricSeanDelaney

I live in switzerland mate, here we have hillclimb championship with two S4 in the entry list! you can trust me, the sound is freakin awesome!

i just seen both then in the Automotoretro in Turin, this morning! they were amazing, obviously!

Deffinately an ingenious idea. Legendary people involved for sure. However(And I understand this is setup/engineered for rallying) am I the only one wondering why he is bogging out whilst drifting donuts w/nearly 400 ft lbs of torque in a racecar at just over 2K lbs?

Still awesome vid and post!

Deffinately an ingenious idea. Legendary people involved for sure. However(And I understand this is setup/engineered for rallying) am I the only one wondering why he is bogging out whilst drifting donuts w/nearly 400 ft lbs of torque in a racecar at just over 2K lbs?

Still awesome vid and post!

This topic is a companion one to the BMW Apfelbeck "radial valve" discussions and the Staggervalve US sprint car engines going back to the Frontenac of the Chevrolet brothers. Can you believe such a fourvalve concept on top of a Ford Model T? Yep. Anyway, I tried hotlinking Dino's commentary to my Facebook blog, Looking Back Racing, but as usual it went awry or someplace I haven't yet found. Please, someone, help by sending it to my page, and of course linger there if you find it otherwise interesting. Cheers!

Rodrigo Coutinho Rod, please share it with my Facebook blog, Looking Back Racing. I tried hot linking but I have about a ten percent success rate doing so.

I heard that Lombardi build a prototipe car with the Triflux engine for hillclimb/drag racing.

The latest work of Lombardi was the Aprilia RSV4 engine

Was the 1985-1986 lancia delta s4 a parallel twin charging system or a series twin charging system ? How does the supercharger & the box above it work between the two intercoolers work on the lancia delta s4 ? Where is the bypass valves on this car ?

Ford did a long and sleek front engined road race car with Bob Riley in the eighties with a conventional large turbo on a 1.7 liter Kent Cosworth engine that claimed similar specific output. It was too much thermal loading for much durability. I did like the chassis concept which anticipated the LMP Panoz with a bit less exaggerated proportions. See my site, Looking Back Racing on Facebook for a posting I will make of it

Reminds me of Fords problematic 1.7 liter belt drive 4 valve with huge turbo and intercooler that made similar output (but only briefly) to power Bob Riley's front engined road race chassis. Back in the eighties. Too much thermal loading. Nice anticipation of the Panoz LMP however.

That Engine Concept is very cool and i still have an idea to improve that technologie,by using Mitsubishi fuel direct injection ... and still an personal special! Who have intressts about that,can write me in Facebook : Marcel Schmidt 92224 Amberg, Bavaria, Germany.

That Engine Concept is very cool and i still have an idea to improve that technologie,by using Mitsubishi fuel direct injection ... and still an personal special! Who have intressts about that,can write me in Facebook : Marcel Schmidt 92224 Amberg, Bavaria, Germany.

@Matt Yes. The camshaft has to be changed to adjust the valve overlap at Lancia's triflux. But does it matter in turbo feed engine?

@Matt Oh yes. But there is no need to overlap the turbo engine.