Visiting a Formula 1 team’s factory is like visiting another dimension. Compared to even the most professionally presented race teams from smaller series, everything in F1 is bigger, more advanced – just more everything. There is constant, frenetic activity: every component the team finish today they start redesigning tomorrow: F1 teams are relentlessly striving for more car performance. Modern F1 teams have to manufacture their cars in as efficient a way as possible to exploit limited resources – both environmental and the FIA’s Resource Restriction Agreement that limits all aspects of a Formula 1 team’s operations, from budgets to personnel to computing power. It’s all about the F1 mantra: make everything as small, as light and as powerful as possible. So, the rare opportunity to see the Lotus F1 factory up close was too good to miss – despite predictably heavy restrictions on photography. (Note that for it’s for this reason that some images are illustrative).

Driving to Enstone, the base of Lotus F1, is a surreal experience in itself. With the post code entered into the GPS, the only thing in the way should have been the traffic on the M25, but as the miles ticked down to the destination I found myself deeper and deeper in the rolling Oxfordshire countryside on smaller and smaller roads. It really didn’t look like the right place to find a state-of-the-art Formula 1 facility.

As the destination point came close it was still fields and farms all round… Except for a low white building just about poking up over the trees.

The final hundred yards down the narrow winding road complete, and out of the trees emerged a small turning: an old-fashioned stone wall, but with a shining Lotus F1 Team sign attached. So, this was it!

Pheasants, foxes and… Formula 1 cars? The Whiteways Technical Centre was constructed by the then-Benetton team back in 1992 on the site of a disused quarry, so the whole facility sits low in a depression in the terrain and makes little impact on the environment. The environment is an important part of the work here, and one of the reasons for our visit: the latest addition to the factory is a solar-powered simulator building. So, amongst the overwhelming display of technological prowess and F1 secrets was an interesting message about the future of the sport.

Lotus F1 CEO Patrick Louis takes a very pragmatic approach to the criticism that Formula 1 can attract – but also has made sure that the team carry out all their activities in a way that is as efficient as possible on all levels. The team aren’t waiting for the new 2014 engine regulations – due to cut fuel consumption by 50 per cent and have a five percent bio-element – to make changes to the way they operate.

“Formula 1 will never be a green sport – just forget it. It’s got petrol-driven engines into the near future. But the rules are changing and we can reduce the consumption. On the other hand it’s not black and white: each flight leaving Heathrow for New York is creating more emissions than all the F1 cars during a whole season. So we thought, how could we react? The only places we can control are the factory and in the paddock, so that’s where we started to be more intelligent.”

Getting power free of charge from FOM in the race paddock wasn’t good enough for the team. In 2010 they installed Trina Solar photovoltaic panels onto the motorhome in the paddock and now have panels on all the race trucks as well. Paddock guests even have access to a monitor showing how much electricity is being generated. Lotus’ efforts extended to the factory: Enstone consumes an enormous amount of energy each year, but Lotus try and source the most sustainable sources of power: for instance they buy in hydro-generated electricity from Scotland, which is more expensive but sits better with the goals of the team.

These and earlier efforts meant that the Kyoto emission reduction targets for the UK for 2012 were met by Lotus back in 2005. Lotus are also the only F1 team reporting to their local authority on the ecological performance of their factory and the countryside environment it sits in, and even employ specialists to help with monitoring local wildlife.

There is the potential for shocking waste in Formula 1, both in energy and materials, so again Lotus do as much as possible to reduce this. Up to 97 percent of the energy they use is recycled in some form – for example, the energy created by the wind tunnel is stored on batteries and and reused to power it up again. Lotus’ F1 car is approximately 15 percent metals and 85 percent carbon fibre-based.: only 12 percent of the original rough metal content is actually used in the final parts, and titanium and aluminium are expensive materials. The team have a strict system in place to control the waste and avoid contamination, which means that around 85 percent of the surplus metal can be reused.

Facts and figures digested, it was time to take a tour around the facility itself. Modern F1 has a ravenous, Glados-style hunger to test. Nowadays, the question is how you achieve that without either breaking the bank or the regulations. You can’t do it with just numbers, as Virgin F1 showed – all these new technologies must be brought together. For instance, CFD can simulate hot air – you can’t do that in the wind tunnel as the model would melt!

But the wind tunnel will give you real-world reactions that the computer might not register – even scale tyres are used in the tunnel to assess deformation. The simulator then provides another layer. It’s about using each complementary parts of the technological jigsaw to check and verify new concepts. The more data, the more accurate the results – which is especially important this year given the difficulty of assessing tyre performance this year.

The simulator is a key instrument for a modern F1 racing team. It’s not just about allowing a driver to learn a new track – there are cheaper ways of doing that – and it’s not just about supplying information to the race team for Friday morning when they send the car out on track. It goes beyond that: simulators are now used to test an entire virtual car and all its constituent parts as part of the on-going development war. Track time on race weekends and subsequent testing outside them is very limited, so these kind of high-tech simulators are key. They are now instrumental in providing an additional raft of test and verification data in track with the other tools that are available.

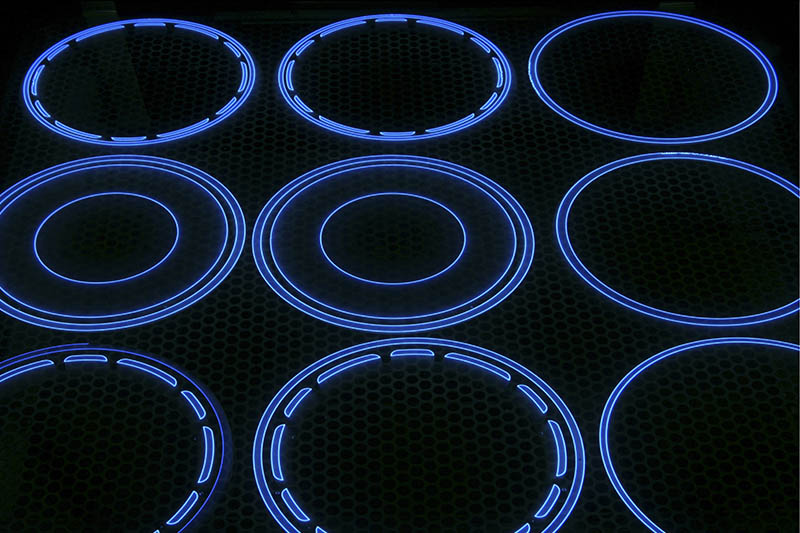

Lotus’ state-of-the-art simulator is their newest toy, and is powered by solar energy. Lotus sponsors Trina Solar have installed a set of 128 panels on the new building’s roof which can generate 33,000kWh of electricity over the course of a year – sufficient to supply more than three-quarters of the total energy the simulator set-up consumes.

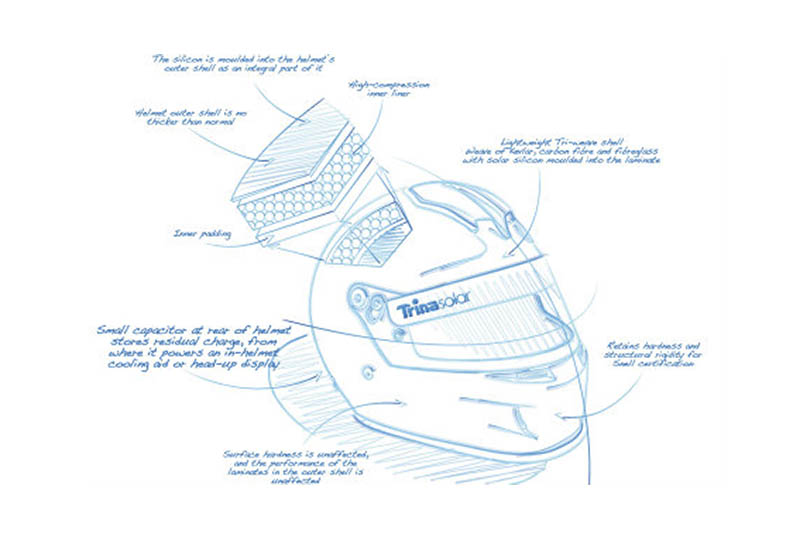

Trina Solar have also been putting their own designers to work, considering future options for integrating their technology into new areas, and research is ongoing to see how silicon can be blended into composite materials to make curved surfaces. One concept they’ve come up with is a silicon-coated race helmet that could generate enough power to work ancillary systems like the in-car radio. In the shorter term they’re also looking at solar-powered pit-wall infrastructures.

Whilst we were Speedhunting at Lotus, in the simulator Lotus reserve driver Jerome D’Ambrosio was driving round a virtual Silverstone Grand Prix track ahead of the weekend’s race. Monitored by two engineers, Jerome pounded round for lap after lap inside the cut-down cockpit mounted on a full-motion platform. During an average day drivers can put in around 100 laps – time is limited because of the potentially disorientating environment.

The engineers can plug in a standard F1 ECU unit into the servers running the system, allowing drivers to test all the features of a modern F1 car, like KERS and anti-stall. It also allows drivers to push that little bit harder in safe conditions to find the limit: Jerome spun when activating KERS too early on the kink coming onto the Wellington Straight, just after the trigger point. These kind of things are valuable lessons for when the race drivers take to the track in anger.

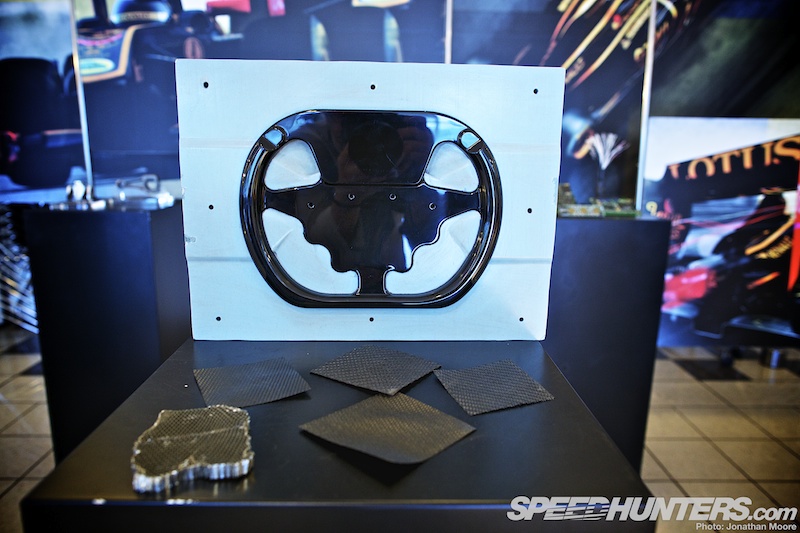

Drivers can also attach their own steering wheels when they drive, as each driver tends to have a custom lay-out they prefer for the myriad dials and switches.

The second strand alongside the simulator is Computational Fluid Dynamics. The most fashionable term in modern racing comes at an enormous price: both in personnel and computing power. Lotus dug up a small hill at Enstone to construct a concrete bunker for their CFD boffins and associated infrastructure, then covered it back up, Teletubbies style.

It all provides excellent thermal efficiency and means the building doesn’t require any heating.

The CFD team have a model of a Boeing airliner and an F/A-18 at the entrance to their office – symbolic of the close links between the aerospace and F1 industries.

Down the corridor is the power behind them: 32.5 terraflops (as regulated by the FIA) of heavyweight computing capacity. 10,000gb of RAM memory. Over 400tb of storage. The system can write the equivalent of two DVDs to disk every second. When their CFD team was formed it provided just 15 percent of measured improvements – it’s now over 50 percent, and the CFD, wind-tunnel and model-making teams currently comprise over 80 people.

The final part is the wind tunnel. Wind tunnels have now been used in racing for many decades, but the physical representation of a car’s behaviour under aerodynamic forces is still used as a prime method of verification.

The model-making team create 60 percent-size replicas for testing in the huge wind tunnel itself, though they also create scale-one items using rapid prototyping and Digital Manufacturing techniques.

Digital Manufacturing is pure science fiction. We’ve all read about 3D printing and similar techniques, but seeing it in action is absolutely breathtaking. For the wind tunnel measurements they can model insanely complex ducting to monitor airflows through the inside of a car on test parts which would be difficult if not impossible to produce using traditional methods. Previously a chrome coating had to be applied to counter wind vibration, but modern materials are now much better and can be used as soon as they come off the machines.

There’s no waste – the laser builds the part up layer by layer. Titanium powder or nylon is used, and incredibly complex shapes can be created with intricate integrated internal layouts. Different materials are used for different applications, all utilising stamped bar codes for identification. Parts are always destroyed after use, as it’s cheaper to remanufacture pieces than to manage and store everything.

For test parts, Initial prototypes are built in plastic and used for a pre-fitting so they can be correctly adapted to the car. It means that the race mechanics can become familiar with a part before they even get their hands on the real thing and cuts down on potential problems track-side. Using this DM technique can be more expensive than traditional technology for large-scale runs, but it’s perfect for one-offs – plus it means that Lotus can rapidly make multiple variations of the same component with tiny variations that can then be run through the wind-tunnel.

The Digital Manufacturing techniques also allow the team to create full-size templates for external suppliers. A full-size gearbox can be ‘printed’ that is then supplied to a foundry. It’s immersed in liquid ceramic, cooked and left to harden. They then blast the mould with heat, which makes the plastic template evaporate, and from the remaining ceramic mould the gearbox can then be cast. Liquid titanium is injected and left to form – then the ceramic is smashed off and a new gearbox hatched and sent back to Lotus for machining and assembly. It’s an incredible process.

The next thing on the tour was Lotus’ seven-post shaker rig, which is all about measuring the contact patch of the tyre to allow accurate suspension set-ups, even taking into account high and low fuel loads. We were shown a virtual lap of Monza – you could really imagine the track as you saw the car react. It’s a very strange thing to watch, as the car is jolted and thrown about by the ghostly machine, but with no steering angle, no driver and a stripped down, Franken-F1 car tied down to the rig.

You really get an idea of the stresses put on the driver – there’s so little movement in the suspension itself, so everything is transmitted straight into the driver’s spine. If you then consider the lateral G, where a driver’s head can weigh the equivalent of 30kg with the high loads in fast corners, and a cockpit temperature which is normally around 60 degrees… Maybe it’s not such an easy job! We were told a story about Fernando Alonso: after 20 seconds watching a car on the rig he was able to identify the circuit (Spa) and that it was him driving! He’s not a World Champion for nothing…

The other side to the team is in the enormous manufacturing area, which handles the more manual construction side of things. Sited in a high-ceilinged warehouse, it much more suits the term ‘factory’ – from the look of the machinery at least. But everything is just as high-tech and delicate, and completed components the result of the very cutting edge of applied manufacturing processes.

The exhausts are all built by hand: cut, bent and welded by the expert fabricators using extremely thin Inconel alloy which ranges from 0.7 down to 0.5mm thin. The exhausts operate at the area of highest temperature on an F1 car, from over 1,000 degrees at the engine to 500 at the exit ports. The exhausts are ‘tuned’ to the order of the cylinders firing to ensure no power is lost, hence the different lengths and twisting, organic look.

There’s a lot of pride and even competition in the factory – if the manufacturing team see a failure on one side or the other of the engine on TV they’ll exactly know who made it…

Back in the championship-winning Renault days, the engineers tuned the throttle to play We Are The Champions on the car’s exhaust: the factory have it on a portable stereo in the warehouse, and are hoping to be able to play it again in public, not just secretly at the factory.

There’s a lot of big machinery taking up the majority of space: five-axis and Electrical Discharge Machining units: both spark erosion and wire erosion techniques are used. These allow the team to manufacture very complex parts and to bond metal to carbon fibre – normally a difficult procedure, as normal machining can damage the structure of the metal due to vibration.

EDM is used to cut the incredibly hard titanium without touching it: a charged soft copper wire is used, which discharges as it approaches the metal and erodes it away. The final objects are gradually cut out of solid blocks, removing section after section until the final – potentially very complex – shape is left. Angles, holes and surfaces can all be eroded into shape.

Charged graphite is used for creating the cut-away sections inside, for instance, a wishbone connector where the carbon fibre rod slots in at one end and the wheel assembly mounts on the other. Even a small part like that can take 24 hours of EDM followed by a several hours of milling.

The target for all F1 cars is to be as light as possible and then to ballast the car back up. Teams want to use the densest material possible for the ballasting to optimise the centre of gravity; Platinum is the densest – but too expensive even for F1. Radium is too dangerous! So the next densest metal, Wolfmet tungsten, is used. We were given a banana-sized piece to hold which was 10kg – your brain can’t comprehend the unexpected weight for such a small object.

Finally we were shown the carbon fibre manufacturing area. The carbon is supplied in rolls of the material with different patterns and thickness depending on the targeted use. The team start with a pattern created from a block of raw material created by a five-axis machine; this then goes to the positively-pressurised clean room for preparation. The laminators attach layers of carbon fibre on to create a ‘negative’ with the appropriate thickness for the part. It’s then vacuum-packed and cooked in an autoclave at around two atmospheres, 135 degrees temperature: this creates the negative mould for the final object.

The resulting carbon goes back into the clean room for them to lay down the final composite layers. All parts are created from CAD drawing masters – the laminators follow that template, which are automatically checked by laser measurements for accuracy. The final ‘positive’ part is again vacuum-packed and returned to the autoclave – this time the pressure is cranked up to seven atmospheres. The negative has to be carbon as it’s the only thing that can withstand the cooking pressure; it’s also important that the mould and final part have the same expansion rate. So you end up with the pattern, mould and final component.

Well, not the final, final part: most of the major panels on the car are actually created from a layered sandwich of carbon with an aluminium or Nomex filling. The honeycomb is very efficient in dissipating the energy from impacts, whilst the carbon makes up for the lack of rigidity of the honeycomb. It’s another F1 technology that has its roots in aerospace.

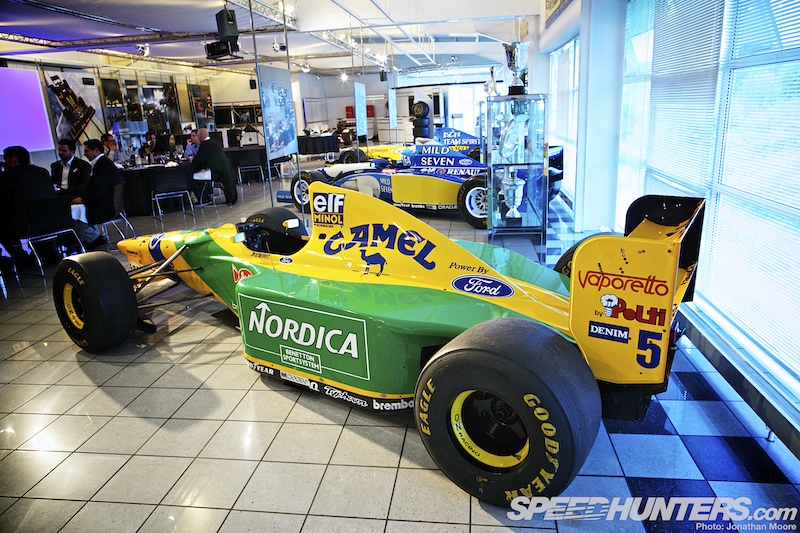

Enstone is home to a team which has operated under various guises, Benetton, Renault and now Lotus, and there’s a deep pride in the factory for all the achievements, no matter the name on the wall. They have won four F1 Drivers’ titles, twice with Michael Schumacher (Benetton, 1994/5) and twice with Fernando Alonso (Renault, 2005/6), also picking up the Constructors’ title in 1995, 2005 and 2006. This history is shown off in the small museum, where several of their older cars are displayed next to current Lotus paraphernalia. Renault powered the B195 from 1995, as it did Williams, but it was Schumacher’s Benetton that came out on top with 11 wins and that year’s title.

The 3.5-litre Ford HBA-powered B193B was driven by Schumacher in 1993, a year where he won once, regularly scored podiums and out-qualified Senna in eight out of 16 races in just his third year in the F1. The B193B was from the active era of F1: it featured active suspension, traction control, a semi-automatic gearbox and for the last two races active rear-wheel steering.

The modern era is represented with the R25 from 2005: Alonso took seven wins on the way to the Drivers Championship. Enstone is the focus here, rather than any specific team name. Even this year’s Lotus F1 car pays tribute to the HQ: the E20 celebrates 20 years at the Enstone facility.

The environmental side might not be as exciting as speed and racing, but if these issues aren’t addressed then motorsport – and that’s everything from F1 down – has a target painted on it. The best thing possible for all of us motorsport fans is that there’s an example set by the big series, so it’s reassuring to see teams like Lotus taking the lead and very interesting to see how they are tackling the numerous challenges.

It always an incredible privilege to see the inner workings of a Formula 1 team and the enormous, around-the-clock effort that goes into the seemingly simple tasks of making two racing cars go round a track in far-flung corners of the world. At Enstone, it’s about when they can return to the winning ways they had as Renault and Benetton. That looks likely to be sooner rather than later.

Jonathan Moore

Additional images courtesy of Lotus F1

That simulator looks amazing, and so does the R25. One of my favorite F1 cars.

Excellent article Mr. Mooore! Thanks for sharing it.

It's so cool to see everything they are doing from an enviormental standpoint... they are really paving the way for the future of F1 & our lifestyle! Oh & that dyno video is awesome!!! They will always be the champions in my book!

Too much to take in even from the screen of my laptop. I can't imagine the excitement of actually being there! Efficiency goes far beyond the border line of obsession here. Win for F1! Awesome coverage!!

Very interesting, but we REALLY didn't need all the "green" crap. Save that for a socialist blog.

The fact that it's nowhere in the countryside adds up to the sci-fi secret facility feel. Awesome. If Kimi and Romain were there that day...

Awesome post. I love seeing more than just the cars, the facility is just as impressive for it's technology and innovation as the cars are for theirs. My only complaint in the article is that's an American Boeing 787, not an Airbus

Yep, how dare they cover the sweet architecture, innovation, and technology of the factory in a FACTORY TOUR, and despite your hate, green technology is really cool and a great direction to develop future technologies and ideas. I'm sure you have plenty of ideas about who I am, but I'm a red blooded, V-8 loving, gun shooting conservative capitalist American, I'm just open to new ideas.

Nice Sci-Fi movie screen shots Mr Moore...=P

Ha! Awesome spot! I must have misheard them – or had my eyes firmly on the Hornet...

@yanes33537 Well, they likely were – the race bays were out of bounds as it was so close to the Grand Prix... And the VIP parking bays out front were all full. With a lot of Lotus road cars as well!

@Dusty Monkey It was interesting – it's a reality that the sport has to deal with, and I really was pleased to see the subject being tackled head on. It's a very positive sign.

@BrandonMotteram The simulator was great. It made my little race seat and wheel set-up at home look rather puny!

As a commercial pilot i'm offended. Airbus doesn't make anything with 787 on the side. I know Europe has a pride thing going for the Airbus, but let's face it. Real airliners have control yokes. Not flyby wire side sick control laws.

This is truly mind blowing. What an incredible post. More race team tours please!?!?!?

This is why I can't get excited over NASCAR... Oh Lotus, how I love thee!

Amazing article, thanks for posting. To me, the wild part is that after all of this ridiculous attention to detail, investment, and effort - they hand the car over to the most unreliable part of the whole process, a human driver. If he's having an 'off' day, or loses focus for one second, all of this tremendous effort can be ruined. Crazy! Respect for the drivers.

Same here. Who says you can't like horsepower and the environment at the same time?

What a silly post.

crazy!!! i for one have made a model out of those 3D printing machines!!!

i could only dream of working in a place like this...hopefully one day it will come true!!

crazy!!! i for one have made a model out of those 3D printing machines!!!

i could only dream of working in a place like this...hopefully one day it will come true!!

crazy!!! i for one have made a model out of those 3D printing machines!!!

i could only dream of working in a place like this...hopefully one day it will come true!!

crazy!!! i for one have made a model out of those 3D printing machines!!!

i could only dream of working in a place like this...hopefully one day it will come true!!

crazy!!! i for one have made a model out of those 3D printing machines!!!

i could only dream of working in a place like this...hopefully one day it will come true!!

Any reason why they don't combine the simulator with the seven-post shaker rig and a rolling road? In my mind - not constrained by finances and petty laws of physics - that could more accurately replace actual on-road testing, plus it would give them a chance to develop and test steering racks for Kimi

As a mechanical engineering student, I am amazed reading this article. The amount of work, research and technology that goes into creating these parts is simply amazing. Some of it borrowed from aerospace --> to F1 ---> and in cases to trickle down into our road going machinery. Great stuff Mr. Moore

Its a toy-factory for man! No doubt about that! I really like the perfection that they use. But one thing kind of took the mood of when I saw the welder just using one glove. That just dumb. Inconell is a material that needs extreme heat when welded. Just like titanium, you need more juice. So that just stupid to weld without gloves or air-mask of all the bad oxides that comes from the metal. I weld alot of titanium, magnesium, inconell, aluminium, stainless etc etc, and I allways use an air-mask when I work. If they have so much money, why dont spend it on welders that know what they are doing. Just a thought.

teletubbies style! haah I'm an engineering student and FULLY appreciate this article. But your jokes are not lost with me. lol keep up the good work.

They alone account for more than 20% of the material used in the UK towards Additive Manufacturing (or DM or RP), then it all goes in a big blue dumpster.

Yep, but your NOT a car fan obvi.

Just one question : Why D'Ambrosio drove in the simulator with the Grosjean's helmet?

@TheExoDozzMRT Ah no, as I mentioned in the introduction, no photography was allowed in the factory so we used images supplied by Lotus F1... No F1 team wants a snapper poking their lens where it doesn't belong!

Love that place. I am amazed at how much energy and how many resources go into being a mid-pack/back marker team.

@Jonathan Moore

oh yea, sorry

Hope Kimi or Romain will win this sunday

and thanks to make us dream!

Best article I have every read, great job writing it and with pictures to explain in more details, 10/10.........GREAT JOB - Cheers Jonathan