Now to continue with the second part of the build up of the Twins Turbo black Supra. In case you missed it, be sure to check part one of the build first.

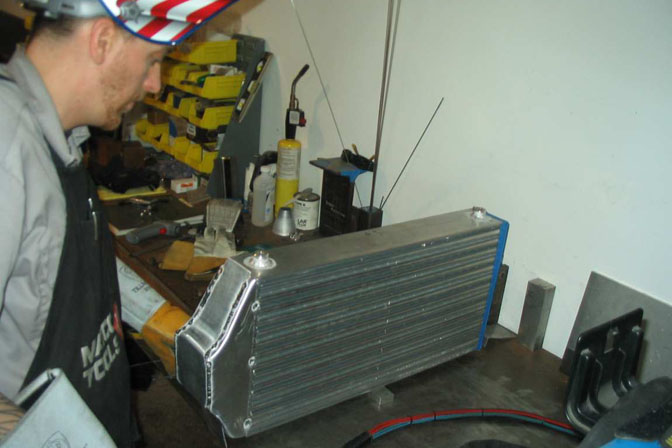

This is the rear mount that supports the radiator and the intercooler, after welding on the bench.

The same mount supporting the rad, and IC, in its position on the project.

Front view of both coolers mocked up, it’s starting to look like something.

Once the intercooler was mounted, it was time to move on to one of my favorite parts of a project like this, the charge pipes. Here is the turbo to IC pipe tacked together, it transitions from 3” at the turbo side to 4” at the IC. Normally we would only use a 4” pipe on the turbo side on a drag car, but the overall short length of the system would balance the diameter, equaling the normal volume of a say 3” inch pipe that is 4.5’ long.

Here’s the pipe mocked up with the IC and turbo.

I'm removing just a little bit … got to be right.

Now that the charge pipe is in place, I can move on to making the IC end tanks. Paper mock up of the shape, and a piece of .090 3000 series aluminum cooling after being annealed.

Round edges are much stronger than a straight bend, that and metal work fascinates me. We chose to take the time and do it right, here I'm using a T dolly and my trusty rawhide mallet to roll an edge.

After hammering out a top and bottom for the end tank, the center was bent up and welded in place, again using 3000 series aluminum .090.

The hot side end tank finished, welded inside and out, welds blended and scotchbrighted for a clean look.

Here’s the hot side of the IC mocked up, looking good man.

Same deal on the cool side of the IC, lots of hammering later we now have a top and bottom tacked in place.

The side was welded in place and blended in, discharge to the throttle is seen being mocked up.

A cool ”fish mouth” cut provides a big gulp for the hungry engine.

Cool side end tank at 90%.

Overall charge cooler system mocked up.

Here’s Carlos finishing the mounting of the blow off valve to the cool side tank.

Once all that room was taken by the charge pipes, it was time to start using whatever little space that was left for an air filter. We're pretty big on air filtration at the shop, something learned doing competitive road racing.

Here’s the 5” air filter pipe snaking its way to what will become the air filter box.

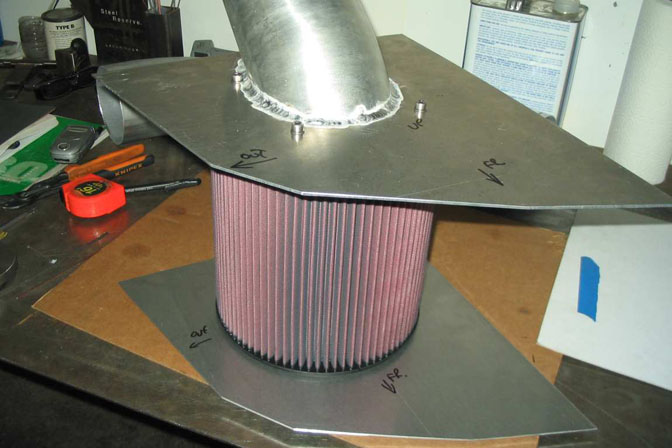

We secured a filter that is normally for a bus, it can double as a interesting hat too.

OK, air filter box is coming around; fitting this thing behind the head light and what not was a challenge.

Air filter on the chassis.

The sides of the filter box are tacked in place, protecting the filter from tire debris and external heat.

Air filter looks GTG, we left the front open so if a plastic bag or similar was blocking the inlet on the nose of the car, it would still be able to run, and not be” out of the fight”.

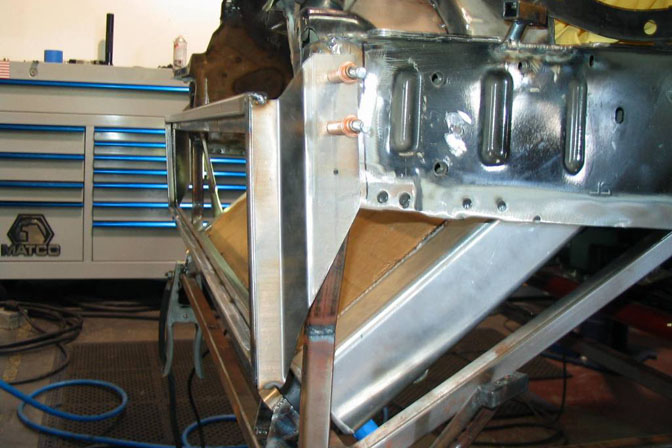

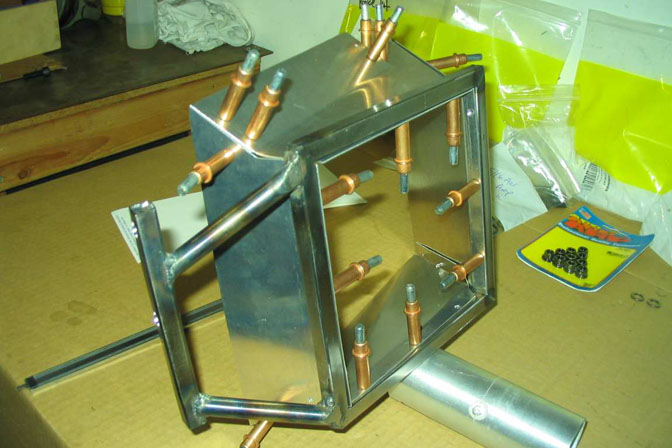

Now that the basics of the front of the car had been laid out, we could now start on the ducting. We learned a long time ago, that proper ducting will make the difference in running a high HP car in any form of competition. Here’s a shot of the basic frame that will support the main air duct. There is a corresponding frame that attaches to the nose, and fits neatly inside this rectangle frame you see here.

Sides of the duct are in place. They are made from 18 gauge (.125) 6061 aluminum.

The frame on the bench. You can see the kleco’s we use to temporally hold everything together, they are normally used in aircraft fabrication, and are really handy when working with sheet metal.

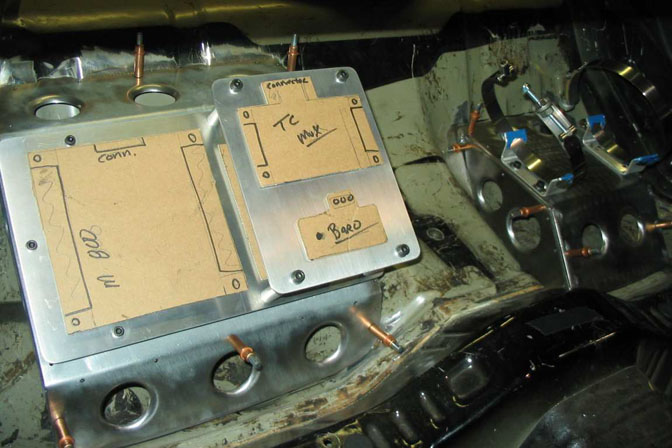

Back to the interior, the rear seat area now houses the ECU condo. And the fire suppression system which will mount to the stand on the driver’s side.

The main duct now incorporates a divider in the middle section, and a scoop that will funnel air off the splitter to the radiator. According to the aero people this is a high pressure zone and should provide solid cooling at speed.

A rear shot of the duct again. The top will feed the IC, and every air molecule will be forced to go across the core. No waste.

Final mock up on the bench.

And on the car.

No wasted airflow here.

Since we removed all factory wiring, we could make a nice mount for our MoTec E888, which will collect the data from the EGT probes mounted it each exhaust runner, and send them to the ECU. Normally this area is taken up by a large relay and fuse box.

There are actually two oil coolers in play on this setup, a C&R heat exchanger behind the rad. and a conventional oil cooler mounted here, front drivers side. We made a frame once the cooler was mounted for proper ducting.

Some sheet metal in play here making the duct come around.. more kleco’s.

The duct mocked up on the chassis.

My brother is always responsible for all the plumbing on the projects that pass through the shop, and during heavy fabrication time he will request we make mounting flanges/ bulkheads ETC for his plumbing. Here is a bulk head array on the bottom of the chassis that will support the oil and fuel lines running from the front to rear of the car.

More plumbing pron, oil / fuel lines.

Here’s Grim using our brown and miller crimp machine to make some lines up, we like to use the best materials and components available. Brown and Miller is the top of the line as far as race car plumbing goes , ask NASCAR, ALMS, F1 and us, light weight, dead reliable. Yes please.

Ahhh gratuitous engine pron, I always enjoy building engines, especially the 2jZ. This example we have here has a billet crank stroker, custom rods, custom pistons, billet main’s, custom rings, custom bearings, custom coatings etc. We came from a drag racing background which gave us good knowledge on how to make big power. When we transitioned to road racing, we learned how to make that power reliable long term.

Fully assembled and on the stand ready to go, you can see the 5 stage dry sump oil pump and crimped/ shielded Brown and Miller plumbing,

There’s a lot more we did but you get the idea. After we were finished welding and grinding, we disassembled the whole thing and sent it out to Auto Explosion in Gardena CA for paint. When it returned it was assembled for real this time, the challenge here was not scratching anything. Hopefully you fellow Speedhunters enjoy the final product.

-Twins Turbo

Amazing job to all at the Twins Turbo shop!!!! Keep up the great work!

OHH god so beautiful. The shot of the overall length of the IC piping and the shot of the bottom of the partially assembled motor/dry sump got me all hot and bothered.

Holy sh#t!! That is some fine fabrication fellas. I think this may be the most insane grip JZA80 ever built..... and it came out of America! Can't wait to see the final product.

welding and fab on the IC is absolutely beautiful, you sir are an artist

Siiiiiiiiiiiiiiiiick

The blog makes it all look so easy. I know what it takes to do all this. Great work and I cant wait to get my car out of there!

HANDS DOWN, BEST BUILD I'VE SEEN YET 5STARS*****

MORE PLEASE

CNDBOOST.INC

Crap! am i seeing this right? It looks like EVERY hole and opening in that eng. compartment has been weld-filled ! For real?

Who doe$ that?! I mean i absolutely HATE bondo'd engine bays,,,, THIS I love.

Hey speedhunters.... will we get to see a finished product??????

OK guys, 18 gauge is NOT .125" Someone should correct that.

Anyway, awesome fabrication!!!

OK guys, 18 gauge is NOT .125" Someone should correct that.

Anyway, awesome fabrication!!!

final product!! can't wait!!

this is custom everything basically...

Proper !

VERY VERY NICE craftsmanship.... Very nice everything.. over time IF the owner is mad as a hatter he could go carbon this and that holder frames. etc.

OMG that ducting!!!!

this thing gonna be 1 of the baddest supras ever built !

incredible metal work especially with the 'fish mouth' bit!! i would love to be able to work on a project like this!

Yes!

this is nothing short of astonishing. what an awesome build, congrats to the twins turbo guys

WOW! that filter is huge! I need one of those, lol

Nice build. This generation is timeless. Love it.

That is an insanely legit build, mad props.

Are you going to use the EGTs for individual cylinder trim adjustments or just to watch? Seems like with that intake your air distribution won't be perfect. Also loving the rad/IC setup, but where's the air go after the heat exchangers? If the exit is in a low pressure area the ducts in the bumper will work even better.

Wow, I'm left speechless. You guys are brutal.

Rad. Thas some serious ish maeng.

$100K build right here...

wow, just wow. I am definitely inspired to do some more ducting on my vehicle now!!

@Josh I couldn't agree more ! soooooo sexy. AMAZING build and magical craftsmanship !

Sweet Jesus. Massive respect for your workmanship. I love the way you guys bring everything from drag to road race experience to bear on these builds. Incredible.

mad fabrication skillz there...never seen so much detail go into a v-mount before. keep up the good work!!

all looking top quality.. another master with the torch!! - want to see the finished product..

Engineering at it's best! Interesting to see all the aero/chassis technologies used in Road Racing cars incorporated into this build. I just hope the exterior body received some love too. Diffuser anyone?

Vagina Boob!

Mother of god....the amount of thought and quality of fab is more and more amazing with every post. I live less than half a mile from your shop and SO wish I could stop by....

? ? ? ? ? you guys for paying attention to internal aerodynamics. They are THE KEY to reliable, large HP figures. It always makes me cringe to watch a build unfold where everything is amazing, they plan ahead, and everything is well fabricated but when they get to the exhaust and intake they introduce foreign flow into a laminar flow (IE wastegate flow exiting and rejoining the exhaust at 90 degrees) and make other such blunders. They will never be able the same kind of numbers that your shop can and they are left scratching their heads as to why. This kind of stuff is what makes me adore your shop.

WOW you guys are putting a V mount in a supra! thats crazy and sooo cool...first time i've ever seen it on a supra before. Keep up the good work guys.

Wow, That is beautiful and very professional. It is always a pleasure to work with you guys. One of these days I need to come by and see you. All the best, Gary

this is immaculate work!!

All we need is some penske's. Haha. Incredible work as usual, guys. Very impressive!!!

Also - that's got to be the shortest IC piping run I've ever seen on a Supra.

Awesome!

This is so legit and gave me so many ideas for my little sr build thank you for sharing guys

innovators.........as always

what is the wrap called on the AN oil lines?

O.o hot damn!!! beautiful machine and work! love supras, cant wait to see this thing in action

as always, hands down to one of THE best Supra builders & fabricators in the country!

its like it never ends....

MUST BE NICE TO HAVE A FAT WALLET.

al 100%!!!!!!!!!!!

Outstanding fabrication, well done on a fantastic build thus far.

Loving ever second of this build!

Gret fab work!

Always nice to see good craftmanship, nice build

holy moly guacamole....

i'm not a fan of mk4's normally but this one is by far one of my favorite builds

Wow... Supra is the best car ever made... PERIOD!

My God that filter is bigger then most turbos!! Just a epic build!

The front ductwork looks a little bit SuperGT-ish doesn't it?

wow im right down the street from you guys. perfect built ! twins turbo is the best especially at supra builts

You guys are sooo awesommmeee :O

wow, super impressive work. I would bet 100K plus to build this beast.

it is really great to see craftsmen at work also. I can never look at that "bolt on kit" the same way again.

And what about that guy Carlos? He is being paid ( i assume) to learn from these guys!!!. that kid is going to be a mega fabricator in a few years.. Hea twins, I will work for free, LOL.... Teach me too!!!!

Carlos. i hate you...J/K..

While this type of build is great (I don't wanna take anything away from Twin Turbo brothers). There are MANY tuning shop that can do the same stuff, and have great attention to detail. Just in California for example the number of tuning shop that work on such builds is staggering. Again, not taking anything away from TT guys. The thing is though, if the customer doesn't have $100k laying around to build such project, the project just ain't happening.

Moral of the story, guys don't wet your pants for this type of crafanship.

I am not disappointed awesome just like I imagined when I win the Lotto, Twins here I come....THanks for the article

I hate Carlos probably twice as much as you. O.k. maybe three times.

alex, name one

Alex - you are not only a douche bag but also a liar.

Name ONE shop in the COUNTRY that can pull this off ? Go ahead , give a name , we don't need a "staggering" number... just one. We can all then click on over to their site and check it out!

P.S. thanks for not 'taking anything away' from this build and this shop - common as dirt as they may be.

The work and the finish of what you have completed is outstanding. I'm very jealous your not working on my car.

Thats amazing work! How many hours of labor do you have in fabbing the intercooler endtanks?

<a href="http://www.poolguysupply.com/blog/tag/jandy-temperature-sensor/">Jandy Temperature Sensor</a> Pool Guy Supply: offering highest quality of Pool Salt Systems, Filter Cartridges, Flow Switch, Salt Chlorine Generator, T-Cell-15, Pentair Whisperflo and Variable Speed Pumps.

Heat exchangers manufacturers are customs built in a wide range of sizes for the application of various fluids, air cooled heat exchanger We have very good experience on making heat exchangers.