For this month's Behind the Scenes theme, guest blogger Cheryl Tay flew to Dijon in France to take a tour of the Stand 21 factory, manufacturers of professional racing helmets and flameproof suits.

Stand 21 is known for their made-to-measure fully customised products.

Besides racing suits, gloves and boots can also be customised with individual designs and colour schemes.

First up, let's have a look inside their helmet production department. The mix of smells within were quite overpowering!

Here's the entrance to the helmet department, where you can see racks of helmets awaiting their finishing touches.

The entire helmet manufacturing process is done within this room.

Here you can see the fabric padding that will form the helmet lining.

A helmet receives a final inspection after assembly. Various additions are added such as straps, visors, drinking straw hole and radio anchors.

Check out the IVOS full carbon helmets, sitting pretty and waiting in line to get painted.

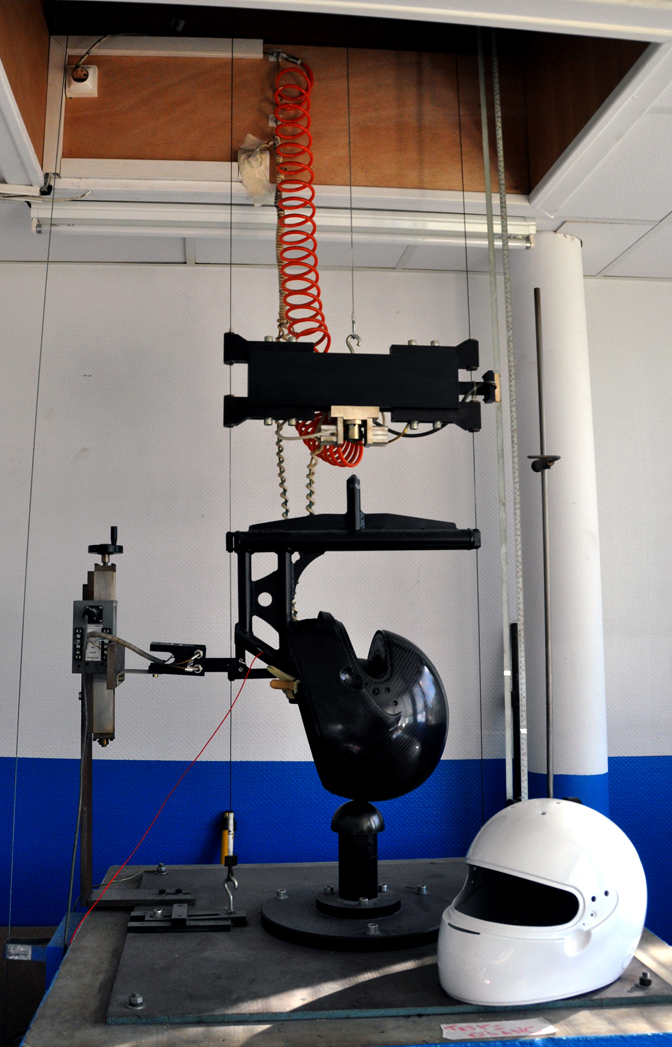

Stringent tests are performed on the helmet designs to ensure they meet Stand 21's internal standards. The helmets are checked once more for quality control before being sent for FIA or Snell testing.

While the helmet production department is filled with men, the suit production department is managed by women.

After the suit design has been finalised, the correct colours of fabric are picked out for production. To keep the drivers cool, Stand 21 have developed a 'Heat Stress Control' fabric called pAIRformance. The fabric breathes, stretches and is homologated for FIA 8856-2000. Stand21 informed me that the fabric was developed after a major medical research programme was undertaken in 2003.

The pieces of fabric then gets ironed and smoothened out.

With the driver’s individual measurements and desired design, the various parts of the fabric used to make the racing suit are cut in patterns.

FIA 8856-2000 standard specifies that embroidery must be done on the outside layer of the racing suit only, so as to avoid any non-fireproof thread getting into contact with the driver’s skin.

Here's a close-up of the embroidery machines at work.

The outside layer of the 2-layer ST3000 Heat Stress Control suit for example, will then be directly sent to the Embroidery Department.

All embroideries are created as a programme and loaded into the computer which controls the machines.

Besides the layers of main fabric for the suit, the different coloured fabrics also need to be added onto the suit one by one according to colour.

The various layers of fabric are then joined together with fireproof thread.

The staff sew an entire suit on their own instead of having a production line where the suit gets passed along.

Once the embroideries on the suit are completed and the fabrics have been sewn together, the suits are ironed and folded.

Once packed, the tailored suits are ready to be shipped to their owners!

A big thank you to the Morizots (Yves, Romain and Christopher) for allowing us behind their factory's closed doors, and for showing us how Stand 21 produce their bespoke helmets and suits!

- Words and photos by Cheryl Tay

Man that lady in the 4th to last pic looks like she's fun to be around.

neat article and great shots! i learned something

Wait....

Cute, likes cars, knows what she's talking about, and takes great pictures?

SHE NEEDS TO BE ADDED TO THE SPEEDHUNTERS ROSTER STAT!

Wow very cool! I never realized how involved this full production of race safety gear could be, Thanks for sharing!

What a great insight into the production. I wouldn't have guessed that the ladies sew an entire suit at a time! Thank you very much, Cheryl!

Thanks for sharing.

" you gotta protect your noggin' " - thanks for an eye opening behind the scenes look at this vital piece of kit! excellent..

lol @ old lady giving you the evil eye

ha that woman didnt look to happy about you taking her picture!!!!

Real fast note, I'm sure Stand 21 knows this, but to everyone on this site, research how beneficial SNELL certification really is before shelling out extra for a helmet with it. Many people, myself included, feel it actually detracts from safety. Just a tip.

Naga_ten needs a beer, because THAT'S EXACTLY WHAT I THOUGHT.

No offense, but if she isn't invited to become a regular blogger here, Speedhunters is officially g**y.

Fully handmande in France for our safety and confort... COCORICO

Thank you all for the support! Will continue working hard to bring more interesting and insightful stories to you! XOXO

XOXO

If only I could have on of those CF helmet.... definitely without paint... CF looks awesome!